Home / Catalog

Catalog Technicians - Precision sowing machines

-

![Pneumatic seeders]()

Pneumatic seeders

-

![Seeders are mechanical grain]()

Seeders are mechanical grain

-

![Precision sowing machines]()

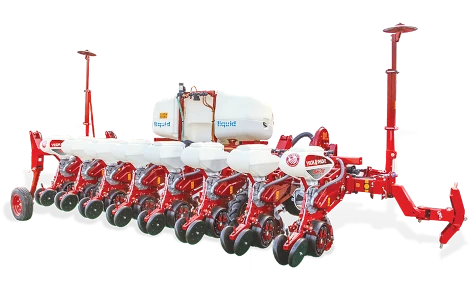

Precision sowing machines

-

![Cultivators <br > for row crops]()

Cultivators

for row crops -

![Cultivators of continuous tillage]()

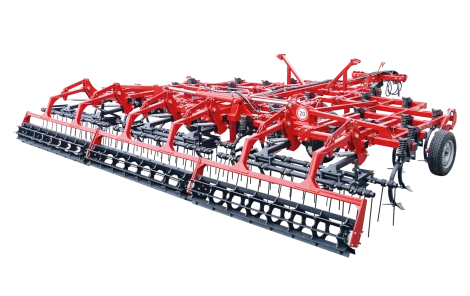

Cultivators of continuous tillage

-

![Disk harrows are two-row]()

Disk harrows are two-row

-

![Disk harrows are four-row]()

Disk harrows are four-row

-

![Sprayers]()

Sprayers

Universal pneumatic seeders are designed for precise sowing of calibrated seeds of corn, sunflower, castor beans, sorghum, soybeans, as well as seeds of forage beans, beans, lupine with simultaneous, separate from the seeds, the introduction of granular or liquid mineral fertilizers and rolling the soil in rows.