Website loading...

Website loading...

Pneumatic seed drill VEGA 8 PROFI is designed for precision sowing using minimum and traditional cultivation technologies. It provides sowing of seeds with the simultaneous introduction of liquid complex fertilizers and rolling of the soil in the sown rows.

It was created to take advantage of modern design solutions that make it possible to significantly reduce the cost of agricultural products on the market.

Mineral fertilizers in liquid form.

Liquid fertilizers are much easier to apply to the soil than granular fertilizers. They are introduced into the soil in the fall for the main cultivation or in the spring for pre-sowing cultivation. They are also used for root and foliar feeding during the growing season of plants.

Liquid complex fertilizers (LCF) - simple and easy to use, moreover, LCF are relatively inexpensive. Such fertilizers can be used in combination with pesticides, which can significantly save financial resources of fuels and lubricants. When using liquid complex fertilizers, losses are no more than 10%, while when using other fertilizers, this figure can reach 30-40%.

VEGA 8 PROFI seeder has a 1 100 liters tank capacity for liquid complex fertilizers . At the bottom of the tank there is a tap for draining the remaining liquid fertilizers.

A 50 l tank for flushing the systems, after liquid fertilizations, is integrated into the main tank.

A 15 liter tank with service water for hand washing is integrated into the main tank.

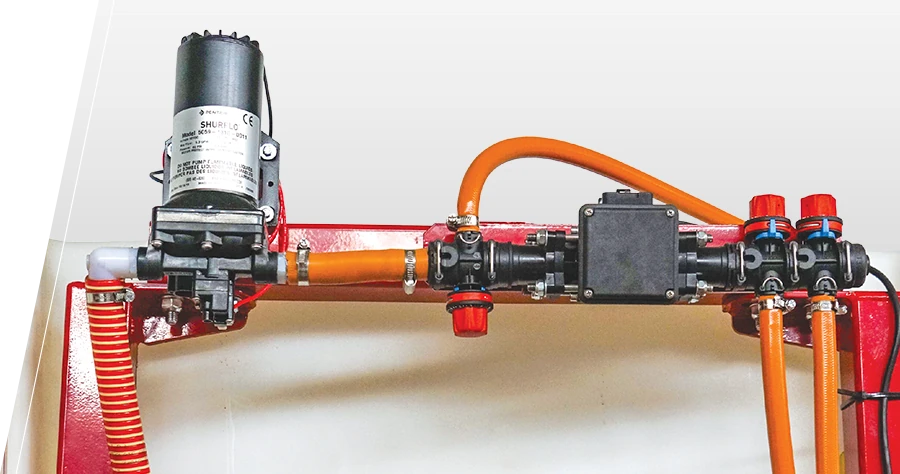

Using an electric pump with a capacity of 21 l/min., by Pentair plant, connected to the tractor's energy system. Liquid fertilizers are supplied through the filter from the tank for 3 adjustable valves (one main and two additional). With the help of valves and a set of washers, the rate of fertilizer delivery to each row is set. Excess fluid is returned back to the tank through a reversible feed system.

Liquid fertilizer is delivered through a hose with a metal tip,which located between the double disc coulter and the press rollers.

Electronic control system is installed on the VEGA 8 PROFI seeders, which monitors the passage of seeds in each opener, the speed of movement and transmits information to a monitor installed in the tractor cab, which allows keeping records of the sown area.

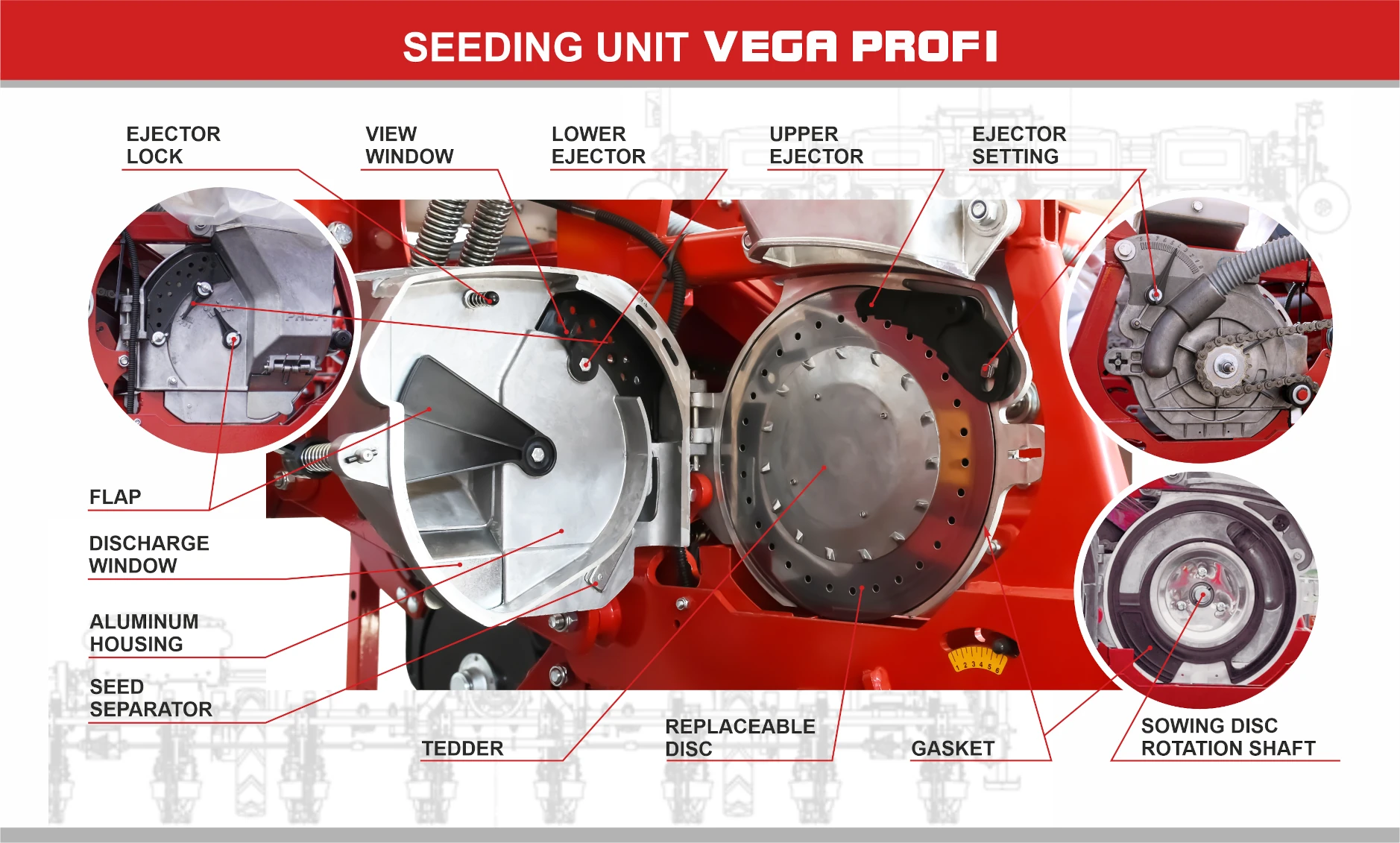

Sowing unit is made of durable aluminum alloys by injection molding, which ensures accurate single-grain seed dosing; its features are as follows:

• presence of upper and lower adjustable seed ejectors, excluding the presence of duplicate seeds;

• amount of seeds falling from the hopper into the sowing chamber is regulated by a flap;

• easy and convenient maintenance without tools;

• a quick-release tedder, installed on the seeding disc, prevents compaction of seeds and getting stuck in the chamber of the sowing apparatus;

• presence of a viewing window makes the adjustment easy;

• sealing gasket is built into the body and has a lip, the erasure of which signals the need to replace it;

• sowing unit is mounted on a frame, which eliminates the influence of loads on it and guarantees durability of use;

• presence of an unloading window ensures complete unloading of seeds after work;

• presence of seeding discs of increased diameter allows to improve the quality of seed placement;

• rotation shaft of the seeding discs is mounted on rolling bearings with increased dust protection, which increases service life.

Seeder with an electric drive is available on an individual order.

Seeding units are driven by electric drives with electronic control and seeding control, combining ease of maintenance, reliability and accuracy of seeding corn, sunflower and other row crops. Seeding rate adjustment is carried out from the tractor cab by the operator using the buttons on the monitor.

With this system, the gearbox, shafts, chains and gears are eliminated from the metering units, there is no need to waste time changing pinions to set a different seeding rate.

Working speed increases.

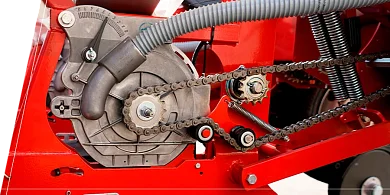

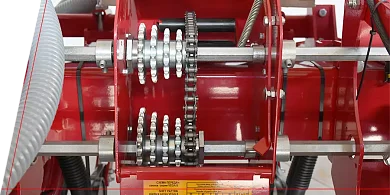

Dynamic design of the chain tensioners on the sections, eliminates chain dropping, during the operation of the drill.

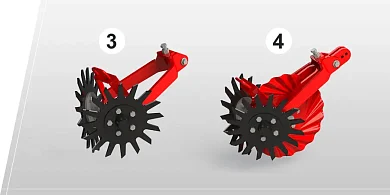

Constant depth control is ensured by spoked wheels mounted on a balancer, which allows each roller to move independently, even when one of the wheels hits an obstacle and unevenness (e.g. stones) without changing the seeding depth. The spoked copying wheels prevent the earth from sticking to the inner surface of the wheel and as a consequence, damage to the bearing unit of the disc coulter hub of the section is eliminated and the service life of the disc coulter is increased.

Cleaners are installed to clean soil sticking on the copying wheels and double disc coulters for sowing seeds, which ensures uniform sowing depth on a wet background.

Disc coulters with new bearing unit. The seeders use double-row ball bearings, which have an increased service life and a greater resistance to dynamic loads.

Precise and easy adjustment of sowing depth is ensured by rotating the handle relative to the scale.

The V-shaped press roller compacts the soil around the seeds and allows moisture to be drawn into the sowing area, which ensures better contact between the seeds and the soil and promotes earlier and more uniform germination.

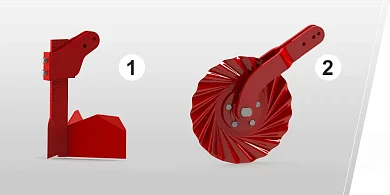

It is installed in front of the working section and ensures removal of clods and dry soil from the sowing area.

*recommended for use with traditional technology.

The unique design of the cutting disc ensures maximum efficiency and high quality cutting of crop residues and soil cutting. The conical waves of the cutting disc cut the soil and effectively loosen the side walls of the furrow directly in front of the coulter. The disc waves enter the soil perpendicular to the surface, which gives maximum cutting effect, and exit the soil parallel to the surface, which allows to “control” ejection of soil.

*recommended for No-Till, Mini-Till with small amounts of crop residues.

This unit is designed to clear the furrow in front of the double-disc coulter from plant debris. It provides the double-disc coulter with uniform and high-quality sowing of row crops.

* recommended for No-Till, Mini-Till with large amounts of crop residues

The design of the cutting disc ensures high-quality cutting of compacted soil. The row cleaner effectively clears the furrow from the abundance of crop residues. This design provides the double-disc coulter with accurate and uniform placement of seeds into the furrow at any soil density.

*recommended for direct sowing with large amounts of crop residues

Seeder is equipped with plastic hoppers made of high quality polyethylene. This, in turn, provides a significantly lower hopper weight; resistance to various types of corrosion; and vibration resistance. In addition, these bins do not require periodic painting.

VEGA 8 PROFI seeder has a total capacity of the seed hoppers - 416 l, and 1100 l - for liquid complex fertilizers.

A gearbox unit of 5x5 gears has been installed, now the farmer has the opportunity to use a wider range of seeding rates, due to the bigger number of gear ratios of the gearbox wheels.

Use of high-pressure hoses of improved quality with double swaging allows the drill to operate under more demanding conditions without the fear of hydraulic fluid leaks and breaks under high pressure.

Usege of high-strength pipes of European steels allows to reduce the weight of the frame structure, while increasing its strength and rigidity, which leads to decreasing tractor fuel consumption.

Frame tube, acting as a receiver, provides a stable value of vacuum in all seeding units (it allows keeping heavy seeds in the holes of the seeding discs of the outer sections).

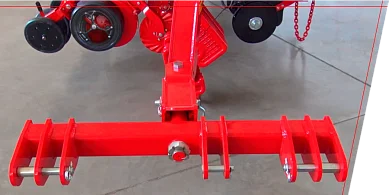

Design of the coupling hitch allows for aggregation with tractors of different manufacturers.

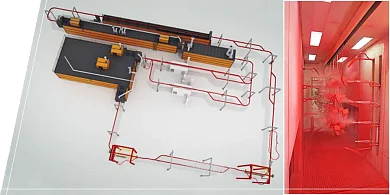

Production line was equipped with a powder coating line -Ideal-line (Denmark). This painting technology makes it possible to produce high-quality paintwork with a guaranteed service life up to 8 years.

Usege of hardware with a strength class, at least 8.8, ensures reliability and durability of exploitation.

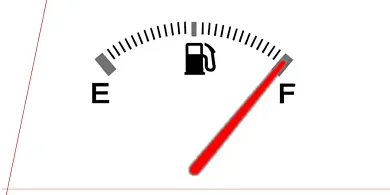

Fuel consumption when working with a 90 hp tractor is 2.6 - 2.9 l/ha.

| Aggregate type | semi-trailed | |

| Operating width, m | 5.6 | |

| Working speed, km/hr | 2.5 - 9 | |

| Number of rows, pcs. | 8 | |

| Capacity, ha/hour | 3.02 - 5.04 | |

| Seeding depth of disc openers, mm | 40 - 100 | |

| Opener pressure, kg/sm² | 280 | |

| Row spacing, mm | 700 | |

| Rate of application of the working fluid, l/ha | 62 - 903 | |

| Box capacity(total) for grains, l (dm³) | 416 (52 х 8) | |

| Box capacity(total) for fertilizers, l (dm³) | 1100 | |

| Overall dimensions for transport, mm | 8 000 х 2 670 х 3 500 | |

| Overall dimensions in position, mm | 2 530 х 6 980 х 1 550 | |

| Coupled with tractors with power, more than h.p. | 80 | |

| Weight, kg | 3 818 | |

* All data and drawings are approximate and non-binding. All rights, to make technical changes to the design reserving to us. Check in more information with the regional manager.