Website loading...

Website loading...

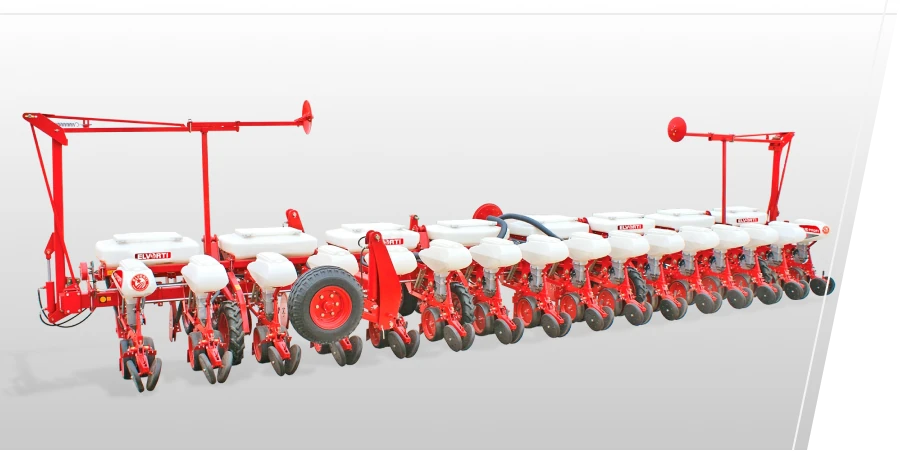

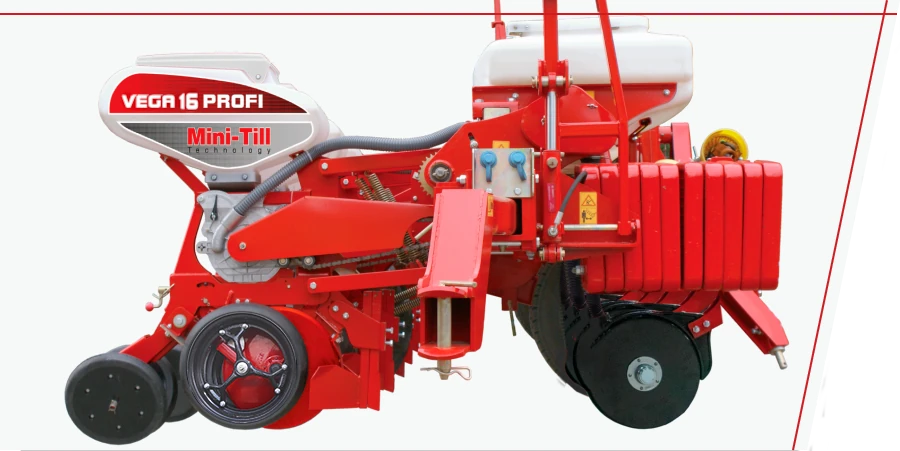

In those farms where liquid mineral fertilizers are applied, the VEGA 16 PROFI seeder can be used without fertilization. This allows it to be aggregated with tractors from 110 hp. (without fertilizer application, the weight of the seeder is reduced to 5390 kg).

Thanks to this method of aggregation, this seeder works with tractors with power from 180 hp, which provides lower fuel consumption compared to mounted counterparts.

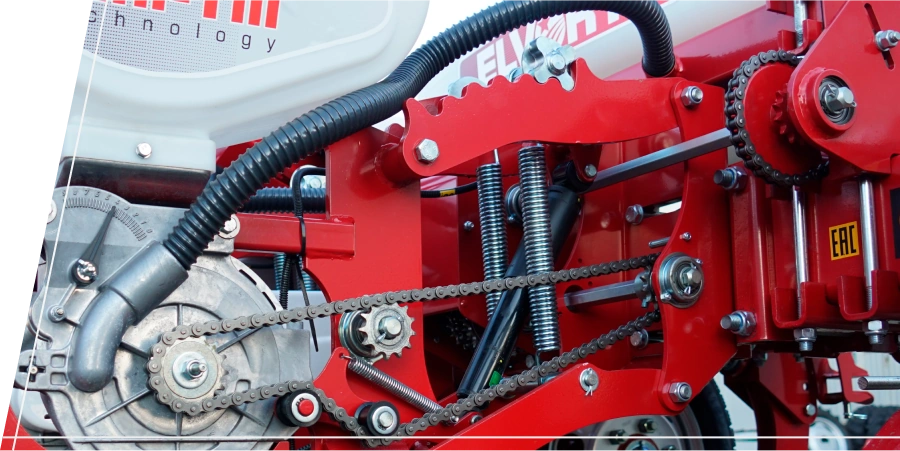

Due to the fact that the fan is installed on the hitch, the possibility of cardan breakage during turns is excluded, and there is no need to turn off the tractor PTO shaft, which eliminates the loss of seed and reduces the time for turning.

Electronic control system is installed on the VEGA 16 PROFI seeders, which monitors the passage of seeds in each opener, the speed of movement and transmits information to a monitor installed in the tractor cab, which allows keeping records of the sown area.

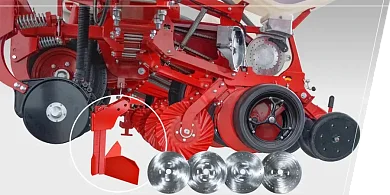

• Double disc coulter made of boron steel of increased hardness has an increased resource up to 100%.

• Ability to regulate pressure on the soil up to 280 kg.

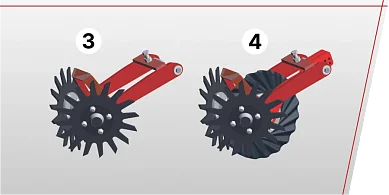

• Ability to use a lump or slotted disc.

• Adjustable V-shaped press wheel.

• Gauge wheels ensure accurate seed placement in depth. Gauge wheels with spokes eliminate soil clogging in the inner cavity of the wheel.

• High position of the sowing unit - excludes clogging with crop residues.

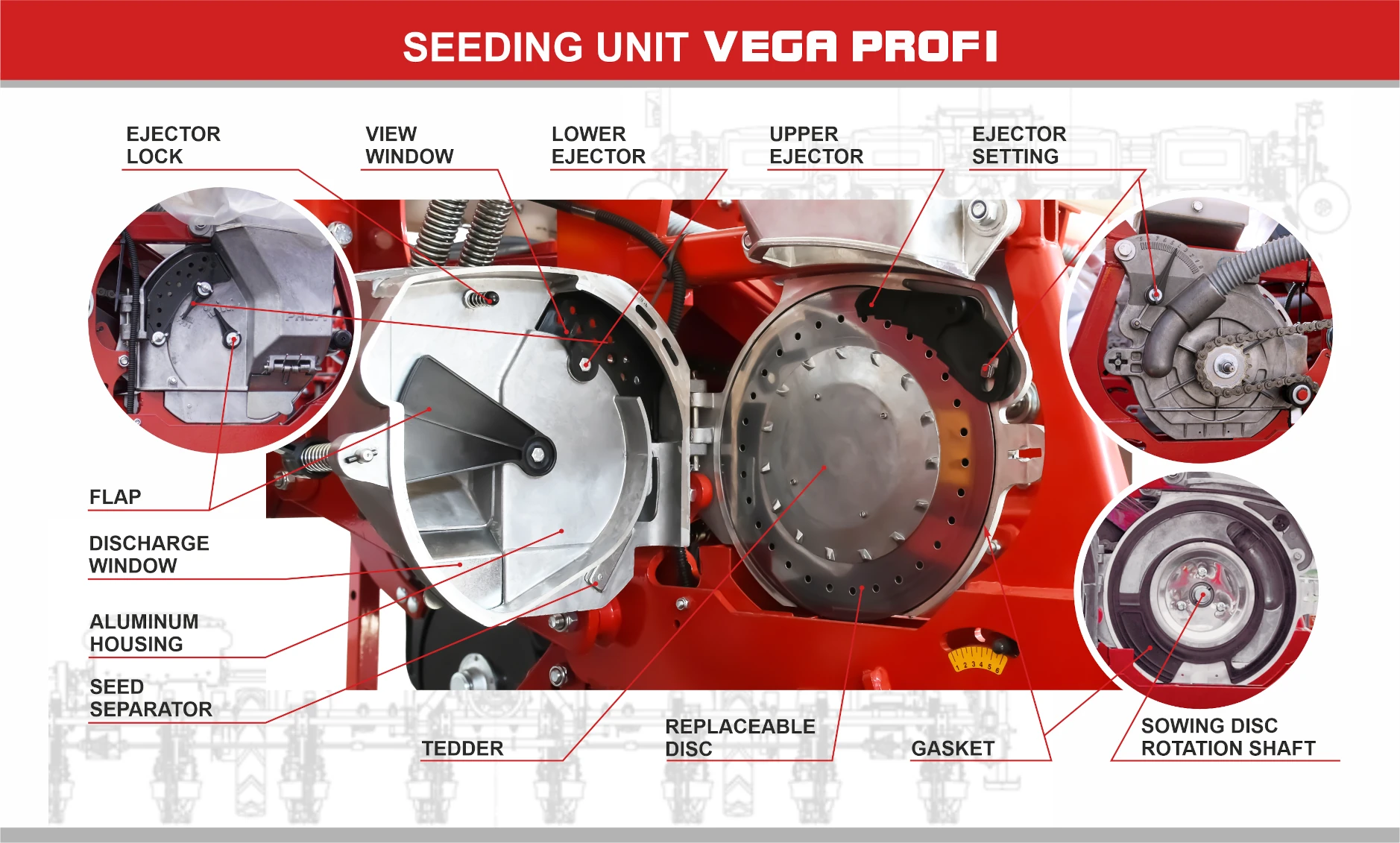

Sowing unit is made of durable aluminum alloys by injection molding, which ensures accurate single-grain seed dosing; its features are as follows:

• presence of upper and lower adjustable seed ejectors, excluding the presence of duplicate seeds;

• amount of seeds falling from the hopper into the sowing chamber is regulated by a flap;

• easy and convenient maintenance without tools;

• a quick-release tedder, installed on the seeding disc, prevents compaction of seeds and getting stuck in the chamber of the sowing apparatus;

• presence of a viewing window makes the adjustment easy;

• sealing gasket is built into the body and has a lip, the erasure of which signals the need to replace it;

• sowing unit is mounted on a frame, which eliminates the influence of loads on it and guarantees durability of use;

• presence of an unloading window ensures complete unloading of seeds after work;

• presence of seeding discs of increased diameter allows to improve the quality of seed placement;

• rotation shaft of the seeding discs is mounted on rolling bearings with increased dust protection, which increases service life.

The section is equipped with a coulter pressure adjustment system, which allows the seed drill to be precisely adapted to various field conditions — from traditional tillage to minimum and zero tillage.

A wide pressure range of 126–220 kgf allows the coulter to maintain the set depth even on compacted or uneven soil.

Adjustment is simple and straightforward — no need to disassemble the section or make unnecessary adjustments in the field.

The result for the farmer:

🌱 Even sowing depth

🌱 Uniform emergence without «waves»

🌱 Stable section operation across the entire area

For working in real field conditions, the section is equipped with a shock absorber that reduces vertical vibrations by up to 20%.

This allows the coulter to smoothly follow the field's contours without losing contact with the soil or changing the seed placement depth, even on lumpy or undulating areas.

The result for the farmer:

⚙️ Stable depth without «bouncing’»

🌱 Uniform germination across the entire field

🕘 Fewer checks and adjustments during sowing

The coulter depth adjustment system is equipped with a calibrated scale that allows you to set the same sowing depth for all sections.

The manufacturer adjusts the scale, so the farmer gets the actual depth value, not conditional marks.

This eliminates differences between rows and ensures synchronous germination and uniform crop maturation.

The result for the farmer:

🌱 Uniform depth across the entire seed drill

🌱 Uniform crop start

🌱 Simple and quick adjustment before sowing

The section has an adjustable rim fit system, that minimizes soil getting between the disc and the rim.

This is particularly important when working on wet and sticky soils, where clogging often leads to jamming, stoppages and loss of sowing quality.

The result for the farmer:

⚙️ Stable operation without clogging

⚙️ Smooth disc rotation

🕘 Less downtime and maintenance in the field

To ensure reliable contact between the seeds and the soil, the section is equipped with adjustable compaction rollers.

The farmer can adjust:

· The pressure from 18.4 to 52.5 kgf;

· The angle of attack of the rollers, adapting the operation to the type of soil and its moisture content.

This ensures optimal seedbed compaction without over compaction or damage to the soil structure.

The result for the farmer:

🌱 Better seed contact with moisture

🌱 Uniform germination

🌱 Strong and uniform crop emergence

Disc coulters with new bearing unit. The seeders use double-row ball bearings, which have an increased service life and a greater resistance to dynamic loads.

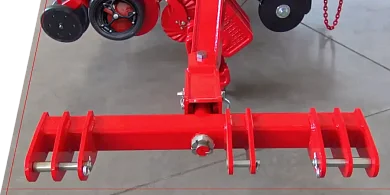

It is installed in front of the working section and ensures removal of clods and dry soil from the sowing area.

*recommended for use with traditional technology.

The unique design of the cutting disc ensures maximum efficiency and high quality cutting of crop residues and soil cutting. The conical waves of the cutting disc cut the soil and effectively loosen the side walls of the furrow directly in front of the coulter. The disc waves enter the soil perpendicular to the surface, which gives maximum cutting effect, and exit the soil parallel to the surface, which allows to “control” ejection of soil.

*recommended for No-Till, Mini-Till with small amounts of crop residues.

This unit is designed to clear the furrow in front of the double-disc coulter from plant debris. It provides the double-disc coulter with uniform and high-quality sowing of row crops.

* recommended for No-Till, Mini-Till with large amounts of crop residues

The design of the cutting disc ensures high-quality cutting of compacted soil. The row cleaner effectively clears the furrow from the abundance of crop residues. This design provides the double-disc coulter with accurate and uniform placement of seeds into the furrow at any soil density.

*recommended for direct sowing with large amounts of crop residues

Seeder is equipped with plastic hoppers made of high quality polyethylene. This, in turn, provides a significantly lower hopper weight; resistance to various types of corrosion; and vibration resistance. In addition, these bins do not require periodic painting.

VEGA 8 PROFI seeder has a total capacity of the seed hoppers - 832 l, and 1440 l - for fertilizers. So, for example, at the seeding rate of corn - 5 seeds per 1 running meter - the seeder can sow 14 hectares without additional loading.

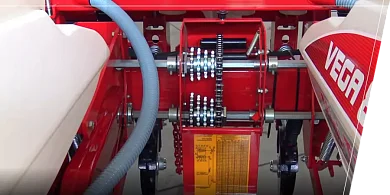

A gearbox unit of 5x5 gears has been installed, now the farmer has the opportunity to use a wider range of seeding rates, due to the bigger number of gear ratios of the gearbox wheels.

This system represents polymer seeding units with polymer reels that are not subject to corrosion, and it enables to quickly and smoothly change the application rate by turning the adjustment knob. Thanks to this, there is no need in a device for changing fertilizer application rates.

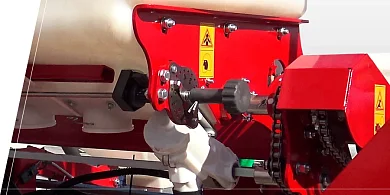

Usege of double-disc fertilizer openers on Vega seeders has improved the quality of soil fertilization. By the consumers request, single-disc fertilizer openers could be installed on the seeder,optionally.

The fertilizer bunker is equipped with a protective screen for fertilizers screening, which helps to prevent the ingress of stones and large objects that can disrupt the operation of the seeder.

Due to the fact, that the fan is installed on the trailer unit, the possibility of cardan breakage during turns is excluded, and there is no needs to turn off the tractor PTO shaft, which eliminates the loss of seeds and reduces the time for turning around.

Use of high-pressure hoses of improved quality with double swaging allows the drill to operate under more demanding conditions without the fear of hydraulic fluid leaks and breaks under high pressure.

Transportation device in the basic configuration, provides additional protection against tire damage by plant stems and other objects on the surface of the field, with a transport width of 2.67 m allows you to move the seeder on public roads.

Design of the coupling hitch allows for aggregation with tractors of different manufacturers.

• 4 sets of seeding discs;

| Sown crop | Diameter of holes, mm | Number of holes, pcs. |

|---|---|---|

| Corn, castor oil plant, broad beans, beans | 5.5 | 30 |

| Sorghum, sunflower (fines) | 2.2 | 40 |

| Sunflower | 3.0 | 30 |

|

Corn

|

4.0 | 30 |

• clod(lump) disposal set;

•cutting disks set;

• information device "HELIOS";

• transportation device.

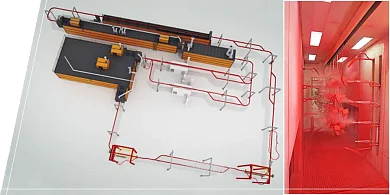

Production line was equipped with a powder coating line -Ideal-line (Denmark). This painting technology makes it possible to produce high-quality paintwork with a guaranteed service life up to 8 years.

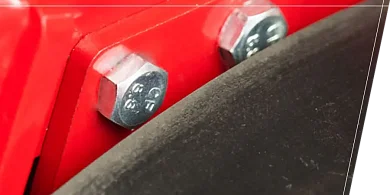

Usege of hardware with a strength class, at least 8.8, ensures reliability and durability of exploitation.

| Aggregate type | semi-trailed | |

| Operating width, m | 11.2 | |

| Working speed, km/hr | 2.5 - 9 | |

| Number of rows, pcs. | 16 | |

| Capacity, ha/hour | 4.0 - 14.4 | |

| Seeding depth of disc openers, mm | 40 - 100 | |

| Opener pressure, kg/sm² | 280 | |

| Row spacing, mm | 700 | |

| Seeding rate for fertilizers, kg/ha | 54 - 536 | |

| Box capacity(total) for grains, l (dm³) | 832 (52 х 16) | |

| Box capacity(total) for fertilizers, l (dm³) | 1 360 (170 х 8) | |

| Overall dimensions for transport, mm | 13 100 x 3 325 x 3 460 | |

| Overall dimensions in position, mm | 6 125 x 12 565 x 2 795 | |

| Coupled with tractors with power, more than h.p. | 180 | |

| Weight, kg | 6 740 | |

* All data and drawings are approximate and non-binding. All rights, to make technical changes to the design reserving to us. Check in more information with the regional manager.