Website loading...

Website loading...

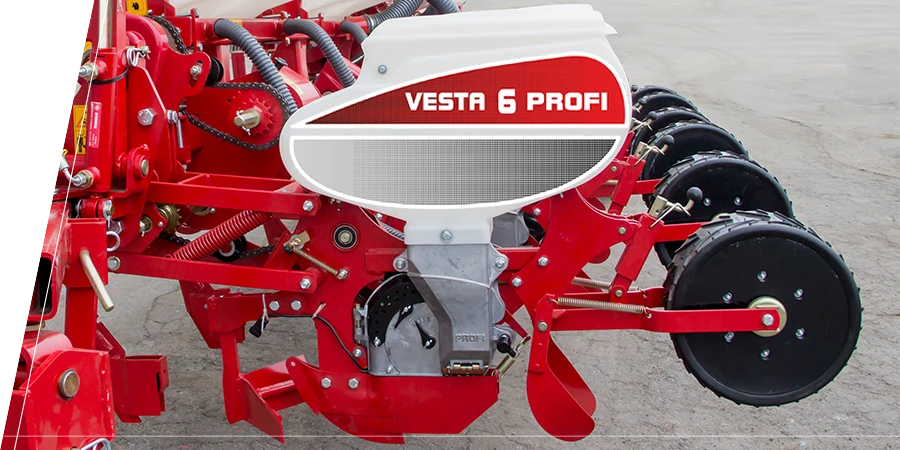

VESTA 6 PROFI – is a pneumatic precision air seeder with a high level of seed placement accuracy using conventional tillage technology. Its main characteristics are ease of use, precision and reliability.

It controls the passage of seeds in each opener, the speed of movement and transmits information to the monitor, allows keeping records of the sown area. This makes it possible to quickly correct deviations.

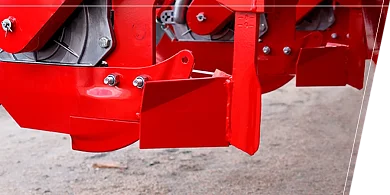

Low positioning of the seeding unit - due to the minimum distance from the point of dropping the seeds to the seeding bed, the accuracy of seed placement in the row is ensured.

• Provides accurate single-grain dosing and sowing of seeds;

• Availability of upper and lower adjustable dumpers of excess seeds - no doubles;

• Easy and convenient maintenance without tools;

• No load on the housing of the sowing device - durability of the sowing device.

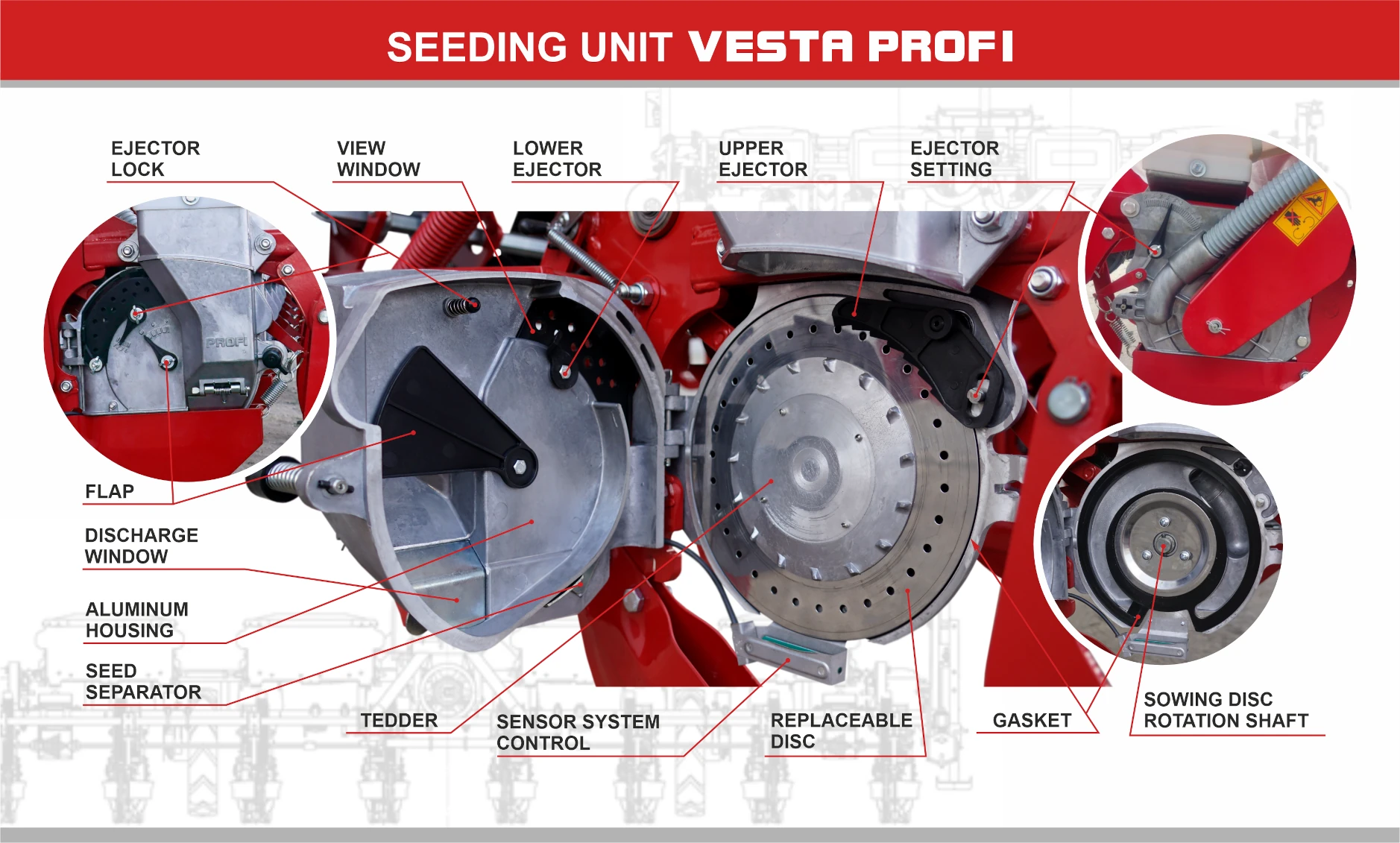

The sowing unit, made by injection molding from durable aluminum alloys, provides precise single-grain seed dosing; its features are as follows:

• the presence of upper and lower adjustable seed ejectors eliminates presence of duplicate seeds;

• the amount of seeds falling from the hopper into the seeding chamber is regulated by a flap;

• easy and convenient maintenance without tools;

• quick-release tedder installed on the seeding disc prevents compaction of seeds and getting stuck in the chamber of the sowing unit;

• the presence of a viewing window provides ease of adjustment;

• sealing gasket is built into the body, and it has a lip, the erasure of which signals the need to replace it;

• the sowing unit is mounted on a frame, which eliminates the influence of loads on it and guarantees durability of use;

• the presence of an unloading window ensures complete unloading of seeds after work;

• the presence of seeding discs of increased diameter allows to improve the quality of seed placement;

• installation of the rotation shaft of the seeding discs on rolling bearings with hightened dust protection increases service life.

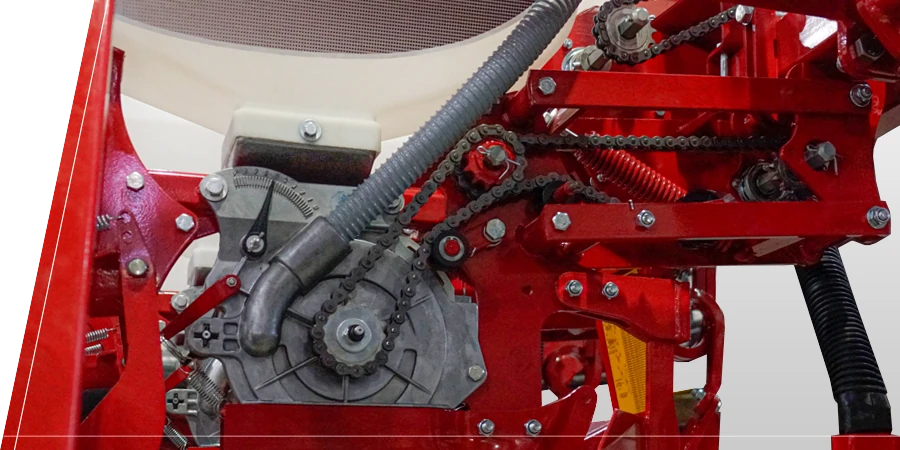

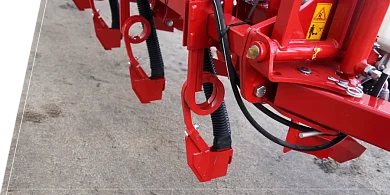

Sowing section was equipped with a 2-contour drive. Reliable drive protection provides work in the fields, weedy plant residues.

The installed clod remover allows sowing even in fields with crop residues and clods.

The combined skid coulter ensures perfect furrow opening. Replacement of a worn heel is quick and easy, ensuring long life of coulter.

The furrow closing mechanism returns the soil to the sown seeds, creating the best possible germination conditions for them.

The press wheel gently compacts the soil in the furrow, improving seed contact and thus ensuring uniform seedlings. The adjustment screw knob sets the optimum seed placement depth from 4 - 12 cm.

Seeder is equipped with plastic hoppers made of high quality polyethylene. This, in turn, provides a significantly lower hopper weight; resistance to various types of corrosion; and vibration resistance. In addition, these bins do not require periodic painting.

VESTA 6 PROFI seeder has a total capacity of the seed hoppers – 216 l, and 560 l – for fertilizers. So, for example, at the seeding rate of corn – 5 seeds per 1 running meter- the seeder can sow 5.6 hectares without additional loading.

A 5x5 star assembly unit has been installed, now the farmer has the opportunity to use a wider range of seeding rates due to a larger number of transmission ratios of the transmission mechanism stars.

This system represents polymer seeding units with polymer reels that are not subject to corrosion, and it enables to quickly and smoothly change the application rate by turning the adjustment knob. Thanks to this, there is no need in a device for changing fertilizer application rates.

Fertiliser coulter is designed for furrow preparation, compaction of the furrow bottom and placement of fertiliser in the soil. It is suitable for well prepared soil and in particular for fine-grained soils with very little plant residues in the surface layer.

The fertilizer bunker is equipped with a protective screen for fertilizers screening, which helps to prevent the ingress of stones and large objects that can disrupt the operation of the seeder.

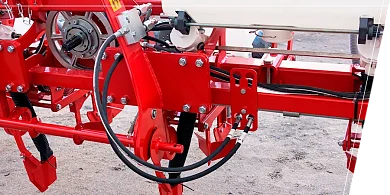

Tube frame that serves as a receiver design with individual access to the diagonal section provides uniform underpressure in all of the sowing apparatuses (allows to keep the seeds in heavy holes sowing disc end sections), thereby allowing to achieve a high quality of all the sowing row crops and other crops.

Use of high-pressure hoses of improved quality with double swaging allows the drill to operate under more demanding conditions without the fear of hydraulic fluid leaks and breaks under high pressure.

Use of high-strength steel pipes of European design reduces frame weight while increasing its strength and rigidity, which reduces the fuel consumption of the tractor.

The transportation device in the basic configuration, provides additional protection against tire damage by plant stems and other objects on the surface of the field, with a transport width of 2.67 m allows you to move the seeder on public roads.

• 4 sets of seeding discs;

| Sown crop | Diameter of holes, mm | Number of holes, pcs. |

| Corn, castor oil plant, broad beans, beans | 5.5 | 30 |

| Sorghum, sunflower (fines) | 2.2 | 40 |

| Sunflower | 3.0 | 30 |

|

Corn

|

4.0 | 30 |

• A set of clodd up

• Information device

• Transportation device

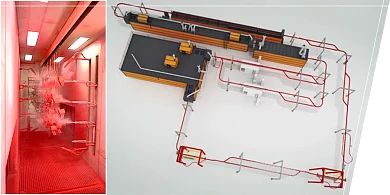

Production line was equipped with a powder coating line -Ideal-line (Denmark). This painting technology makes it possible to produce high-quality paintwork with a guaranteed service life up to 8 years.

Fuel consumption when working with a 80 hp tractor is 2.3 l/ha.

| Aggregate type | mounted | |

| Operating width, m | 4.2 | |

| Working speed, km/hr | 2.5 - 9 | |

| Capacity, ha/hour | 1.05 - 3.78 | |

| Row spacing, mm | 700 | |

| Seeding rate for fertilizers, kg/ha | 54 - 536 | |

| Box capacity(total) for fertilizers, l (dm³) | 560 (280 х 2) | |

| Coupled with tractors with power, more than h.p. | 75 | |

| Weight, kg | 1 090 | |

* All data and drawings are approximate and non-binding. All rights, to make technical changes to the design reserving to us. Check in more information with the regional manager.