Website loading...

Website loading...

Mounted pneumatic seed drill VEGA 6 PROFI with telescopic frame is designed for precision seeding while using the minimal technology of soil cultivation. It can used for sowing seeds of corn, sunflower, soybean and other tilled crops with simultaneous application of mineral fertilizers and soil compaction in sown rows.

☑ Increasing productivity due to the option to higher the sowing speed up to 15 km/h without losing the quality of seeding.

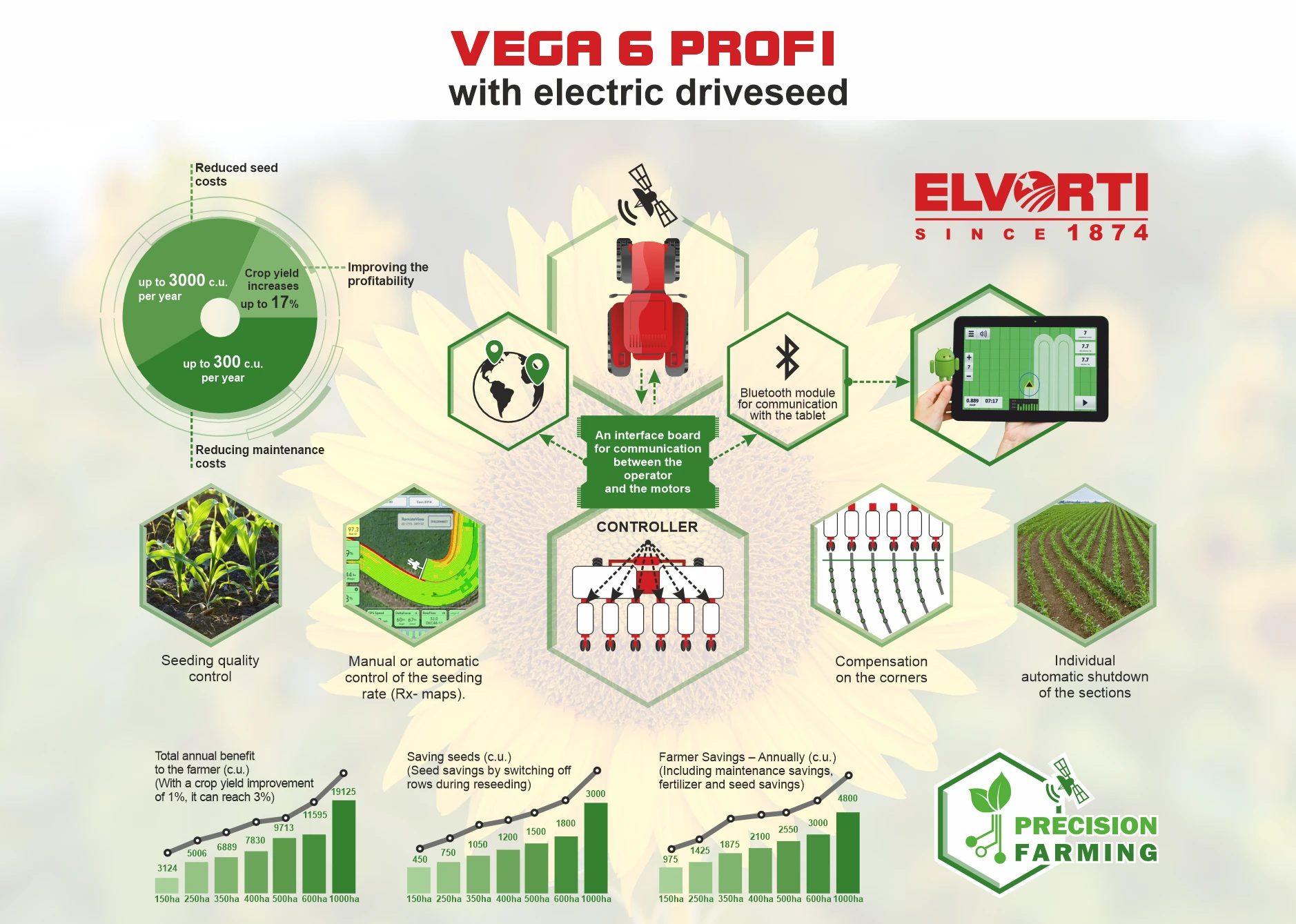

☑ Increasing uniformity of the seeding rate achieved due to the use of an electric drive. The seeding rate does not depend on the speed and slippage of the wheels, which eliminates gaps.

☑ The accuracy and range of the seeding rates setting enhanced. The electric drive allows adjusting various seeding rates in a wide range crops.

☑ Time saved when changing crops and changing the seed rates. Easy and smooth adjustment on the tablet from the tractor cab.

☑ Reducing the cost of seed up to 3 000 euros per year (taking into account the area under cultivation of 1 000 ha) due to the elimination of reseeding.

☑ Savings in spare parts and maintenance costs of up to 400 euros per year by reducing the number of operating units.

☑ Crop yield increases up to 17% using options PRO AFP.

☑ The total savings of the farmer, taking into account the above, is up to 5 000 euros ha per year (taking into account the area under cultivation of 1 000 ha).

☑ This planter works with class 1.4 tractors.

Thanks to this method of aggregation, this seeder works with tractors from 100 hp, which provides better manoeuvrability than its trailed counterpart.

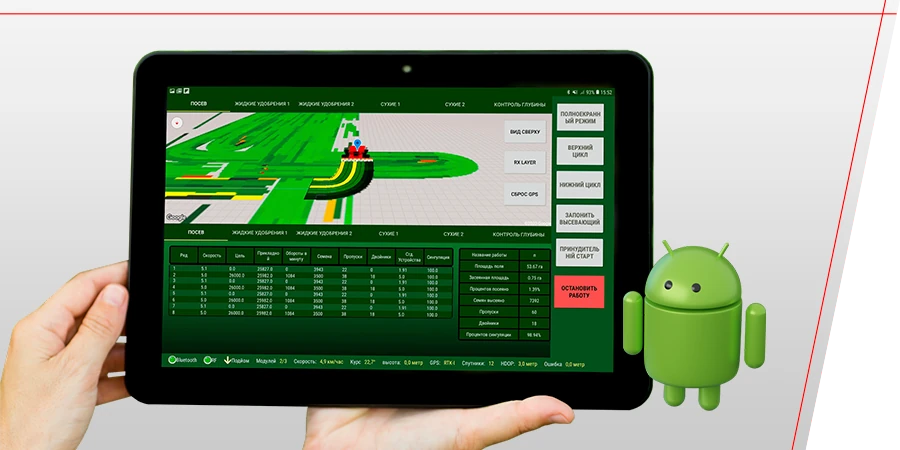

The installed electric drive and software provide for the following functions using a tablet from the tractor cab:

- individual automatic shutdown of the sections;

- ordinal control of the variable seeding rate;

- compensation on turns of the angular speed of rotation of each seeding unit;

- manual or automatic control of the seeding rate by Rx task maps;

- seeding quality control in the form of histograms;

- generation of reports based on maps of actual introduction;

- motor rotation speed adjusted by manually entering the necessary parameters, or through a signal - from third-party GPS receivers, or a signal from speed radars.

Designed as a wireless system based on Android OS. The tablet connects to the controller that controls the electric drives, by using Bluetooth and a wireless communication protocol. To determine location, the controller integrates with any third party receivers.

VEGA PROFI seeders are equipped with electronic control system that monitors the passage of seeds in each coulter, the speed of movement and transmits information to a monitor installed in the tractor cabin. This allows to keep an accurate record of the sown area.

Sowing sections of the seeder designed to ensure the process of seeds sowing including such stages as formation of a sowing bed, sowing of seeds and rolling the soil over the sown rows.

• A double-disk coulter made of hardened boron steels has an increased resource of up to 100%.

• Pressure on the soil can regulated up to 280 kg.

• Possibility of using a clod remover or slotted disc.

• Adjustable V-shaped press wheel.

• Accuracy covering of seeds in depth ensured by gauge rollers. Discs of gauge rollers with spokes eliminate clogging of soil into the inner cavity of the disc.

• High location of the seed-sowing device eliminates clogging with crop residues.

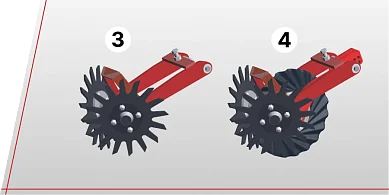

Row cleaners (needle rotors) are optionally available.

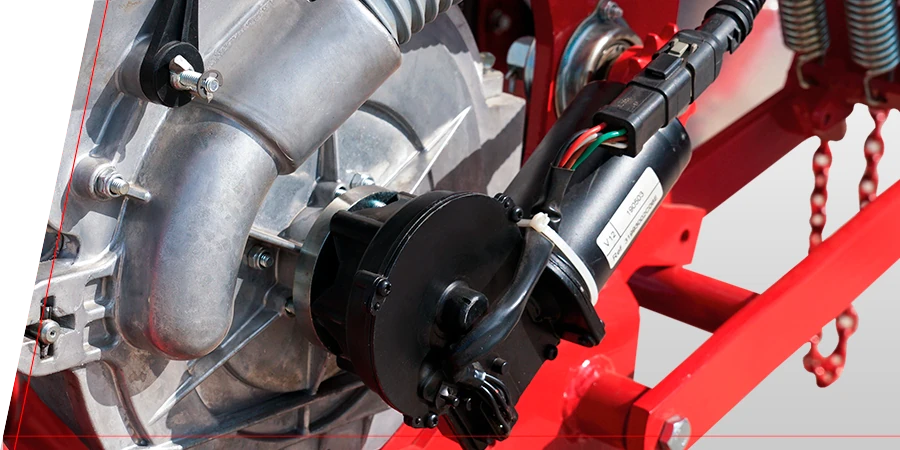

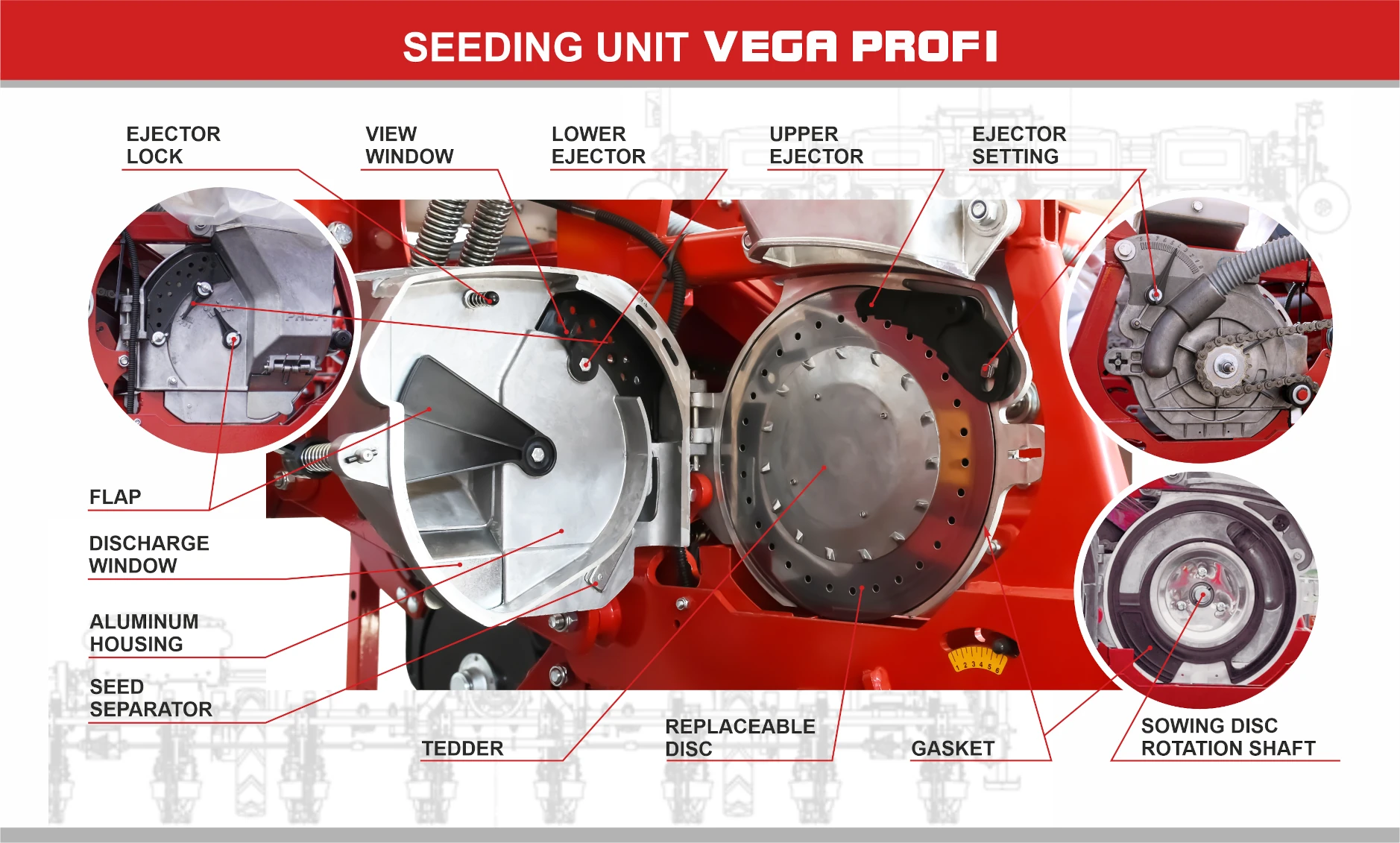

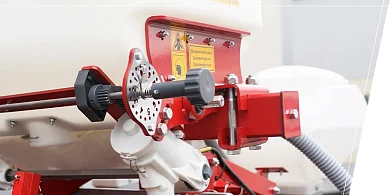

Sowing unit is made of durable aluminum alloys by injection molding, which ensures accurate single-grain seed dosing; its features are as follows:

• presence of upper and lower adjustable seed ejectors, excluding the presence of duplicate seeds;

• amount of seeds falling from the hopper into the sowing chamber is regulated by a flap;

• easy and convenient maintenance without tools;

• a quick-release tedder, installed on the seeding disc, prevents compaction of seeds and getting stuck in the chamber of the sowing apparatus;

• presence of a viewing window makes the adjustment easy;

• sealing gasket is built into the body and has a lip, the erasure of which signals the need to replace it;

• sowing unit is mounted on a frame, which eliminates the influence of loads on it and guarantees durability of use;

• presence of an unloading window ensures complete unloading of seeds after work;

• presence of seeding discs of increased diameter allows to improve the quality of seed placement;

• rotation shaft of the seeding discs is mounted on rolling bearings with increased dust protection, which increases service life.

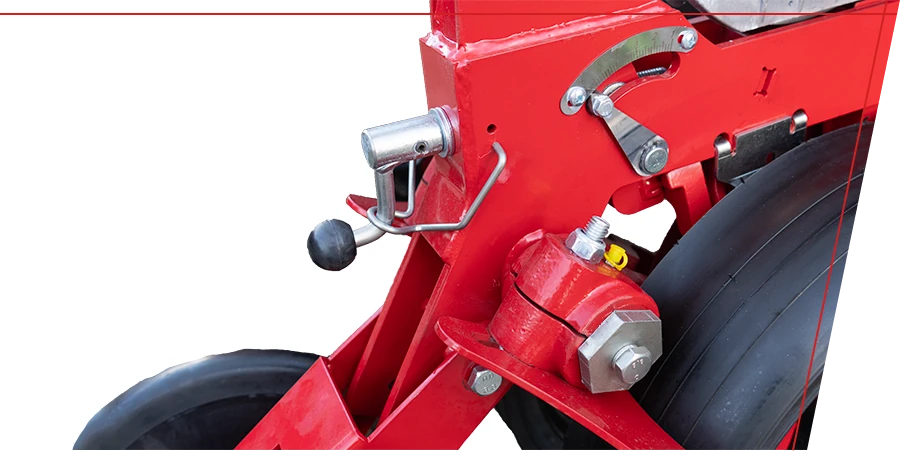

The section is equipped with a coulter pressure adjustment system, which allows the seed drill to be precisely adapted to various field conditions — from traditional tillage to minimum and zero tillage.

A wide pressure range of 126–220 kgf allows the coulter to maintain the set depth even on compacted or uneven soil.

Adjustment is simple and straightforward — no need to disassemble the section or make unnecessary adjustments in the field.

The result for the farmer:

🌱 Even sowing depth

🌱 Uniform emergence without «waves»

🌱 Stable section operation across the entire area

For working in real field conditions, the section is equipped with a shock absorber that reduces vertical vibrations by up to 20%.

This allows the coulter to smoothly follow the field's contours without losing contact with the soil or changing the seed placement depth, even on lumpy or undulating areas.

The result for the farmer:

⚙️ Stable depth without «bouncing’»

🌱 Uniform germination across the entire field

🕘 Fewer checks and adjustments during sowing

The coulter depth adjustment system is equipped with a calibrated scale that allows you to set the same sowing depth for all sections.

The manufacturer adjusts the scale, so the farmer gets the actual depth value, not conditional marks.

This eliminates differences between rows and ensures synchronous germination and uniform crop maturation.

The result for the farmer:

🌱 Uniform depth across the entire seed drill

🌱 Uniform crop start

🌱 Simple and quick adjustment before sowing

The section has an adjustable rim fit system, that minimizes soil getting between the disc and the rim.

This is particularly important when working on wet and sticky soils, where clogging often leads to jamming, stoppages and loss of sowing quality.

The result for the farmer:

⚙️ Stable operation without clogging

⚙️ Smooth disc rotation

🕘 Less downtime and maintenance in the field

To ensure reliable contact between the seeds and the soil, the section is equipped with adjustable compaction rollers.

The farmer can adjust:

· The pressure from 18.4 to 52.5 kgf;

· The angle of attack of the rollers, adapting the operation to the type of soil and its moisture content.

This ensures optimal seedbed compaction without over compaction or damage to the soil structure.

The result for the farmer:

🌱 Better seed contact with moisture

🌱 Uniform germination

🌱 Strong and uniform crop emergence

Disc coulters with new bearing unit. The seeders use double-row ball bearings, which have an increased service life and a greater resistance to dynamic loads.

It is installed in front of the working section and ensures removal of clods and dry soil from the sowing area.

*recommended for use with traditional technology.

The unique design of the cutting disc ensures maximum efficiency and high quality cutting of crop residues and soil cutting. The conical waves of the cutting disc cut the soil and effectively loosen the side walls of the furrow directly in front of the coulter. The disc waves enter the soil perpendicular to the surface, which gives maximum cutting effect, and exit the soil parallel to the surface, which allows to “control” ejection of soil.

*recommended for No-Till, Mini-Till with small amounts of crop residues.

This unit is designed to clear the furrow in front of the double-disc coulter from plant debris. It provides the double-disc coulter with uniform and high-quality sowing of row crops.

* recommended for No-Till, Mini-Till with large amounts of crop residues

The design of the cutting disc ensures high-quality cutting of compacted soil. The row cleaner effectively clears the furrow from the abundance of crop residues. This design provides the double-disc coulter with accurate and uniform placement of seeds into the furrow at any soil density.

*recommended for direct sowing with large amounts of crop residues

The seeder equipped with plastic bunkers made of high quality polyethylene. This provides a significantly lower weight of the bunker, its resistance to various types of corrosion, and vibration resistance. Such bunkers do not require additional painting and are resistant to corrosion from mineral fertilizers.

The total capacity of the seed bunkers of the VEGA 6 PROFI seeder is 312 liters, and the total capacity of the fertilizer bunkers is 560 liters. Thus, for example, when the seeding rate of corn is five seeds per one linear meter, the seeder can sow 3.6 ha without reloading.

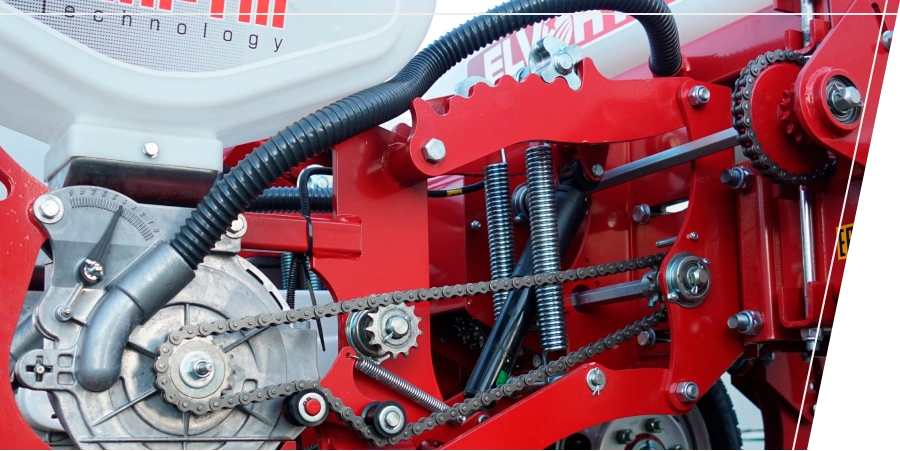

With the 5x5 sprocket assembly, the farmer can now use a wider range of seed rates due to the larger number of gearbox sprocket ratios. One gearbox is used on the drill - for seed rate control. The new fertiliser system eliminates the need for a gearbox to change the fertiliser rate.

The system is a polymer-seeding device with polymer spools, which are non-corrosive, with the ability to quickly and smoothly change the application rate by turning the adjustment knob. This eliminated the need for a gearbox to change the fertilizer rate.

Using of double-disc fertilizer coulters on VEGA 6 PROFI seeders improved the quality of fertilizer distribution in the soil. At the request of the consumer, it is optionally possible to install single- disk coulters for fertilizers.

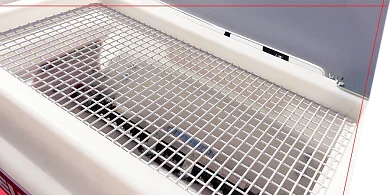

The fertilizer bunker is equipped with a protective screen for fertilizers screening, which helps to prevent the ingress of stones and large objects that can disrupt the operation of the seeder.

The centrifugal fan designed to create a vacuum in the pneumatic system of the seeder. The fan driven from the PTO shaft of the tractor at 540 rpm by a cardan shaft. A centrifugal clutch mounted on the shaft of the lower fan pulley protects the belt drive from increased wear during a sudden stop of the PTO. When the tractor's PTO is disengaged, the fan speed gradually decreases, while a characteristic loud clicking of the rollers can heard in the overrunning clutch of the lower pulley until the rotation stops completely. This is a mandatory regular situation and is nota sign of any defect.

Using of high quality double crimped high-pressure hoses allows operating the planter in more demanding conditions not worrying for hydraulic fluid leaks and high pressure breaks.

The driving wheels designed to move the seeder in the combination with a tractor and in the working position, to transmit torque through the transmission mechanism to the disks of the seed- sowing devices and through the counter drive to the roller feed fertilizer sowing devices. This seeder has the ability to adjust the support-drive wheels in height.

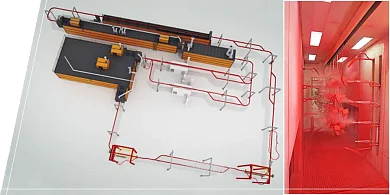

Two installed hydraulic cylinders ensure the unfolding of the frame into the working position, as well as the spacing of 700 mm. When rearranging the brackets (stops) on the extreme holes of the horizontal bars on the seeder, the 750 mm spacing can used. When the frame folded, the transport dimension of the seeder is no more than 3 000 mm forall spacing's.

The markers lowered and raised by a hydraulic mechanism that consists of a hydraulic cylinder and a high-pressure hose, and controlled from the tractor cab. The marker itself folded in half to reduce the height of the seeder.

• Seed disks: 4 sets;

| Crops | Diameter of holes, mm | Number of holes, pcs. |

|---|---|---|

| Corn, castor oil plant, broad beans, beans | 5.5 | 30 |

| Sorghum, sunflower (fine fraction) | 2.2 | 40 |

| Sunflower | 3.0 | 30 |

|

Corn |

4.0 | 30 |

• a set of lump eliminators;

• a set of slotting disks;

• information device.

Production line was equipped with a powder coating line -Ideal-line (Denmark). This painting technology makes it possible to produce high-quality paintwork with a guaranteed service life up to 8 years.

Usege of hardware with a strength class, at least 8.8, ensures reliability and durability of exploitation.

* All data and drawings are approximate and non-binding. All rights, to make technical changes to the design reserving to us. Check in more information with the regional manager.