Website loading...

Website loading...

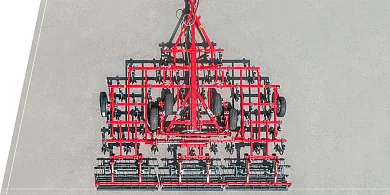

POLARIS PREMIUM – is a semi-trailer cultivator designed for resource-saving pre-sowing and steam soil cultivation for cereals, industrial and forage crops, for cutting and combing weeds, as well as for leveling and compaction of the ground surface. Cultivator models are available with working widths from 4 to 12 meters. One of the advantages of this cultivator is its spacious design, which has a high crop residue throughput capacity. The optimum paw spacing promotes intensive mixing and uniform loosening of the soil.

An important factor in a successful harvest is the quality preparation of the seed bed.

☑ Effective combination of work units

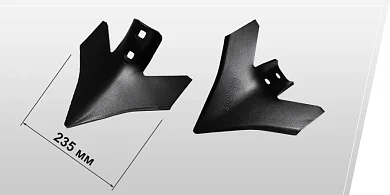

The checkerboard arrangement of the paws in 5 rows with a paw width of 235 mm allows to work on fields with a lot of crop residues without clogging.

☑ The paws work under the action of vibration

As a result of vibration, the paws thoroughly crush the soil and wear less, thereby reducing operating costs and maintenance frequency.

☑ Robust cultivator design

The frame has a lattice design, it is made of high-strength European steels, it provides the necessary strength and reliability with less weight of the cultivator, resulting in a reduced need for tractor traction force.

☑ Reliable transportation

Checkerboard arrangement of tandem wheels ensures smooth passage of crop residues without clogging, stable and uniform tillage depth across the entire working width of the unit.

☑ Quick adjustment of working depth

The depth is easily and quickly adjusted by installing clips on the hydraulic cylinder rods of tandem wheels, as well as by adjusting the support wheel lanyards (talreeps) on the cultivator wings.

☑ Effective moisture preserving

Aggressive teeth of a spring harrow comb out cut weeds, destroying capillarity, evenly mix and distribute plant residues on the field, preserving moisture and promoting the most complete and rapid germination of fallen plants.

☑ High-quality soil compaction and leveling

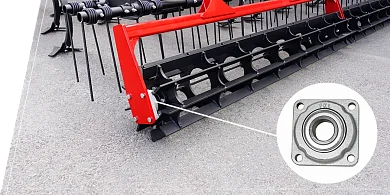

Pressing slatted rollers ensure the crushing of large and small lumps, and also compact the soil in the seed bed area.

The checkboard arrangement of the loosening arms in 5 rows ensures improved flow of crop residues, no clogging, uniform soil distribution and weed cutting. The lattice frame facilitates the flow of large quantities of crop residues due to the fact that the struts have optimal transverse and diagonal spacing, which also reduces the energy costs of tillage.

Polaris 6 Premium is equipped with 25x40 mm struts with permanent spring protection. Thanks to the vibration of the struts, very thorough mixing of the soil is carried out. With constant spring protection, the strut reliably holds the paw at the set depth to create a uniform seed bed in unstable conditions, ensuring simultaneous emergence of seedlings.

The 235mm cultivator paw has a unique wing design and provides a low furrow to optimize productivity and meet the demands of tough field conditions. Paws have Increased service life since they are manufactured of boron steel, and they are hardened for durability and strength while maintaining sharp edge, this ensures their long service life. As a protection against counterfeiting, the manufacturer's marks are placed on the paws of our own production. Reliable bolt-on mounting allows for simple and quick replacement of wear components.

The compacting slat roller ensures crushing of soil, which is dominated by small lumps of soil up to 25 mm in size. Thanks to its radial suspension, the roller follows field unevenness and ensures leveling and compaction of the soil surface. Thanks to the design features of the bearing unit with a 2-year warranty, the service life of the roller is increased and the time for servicing the unit is reduced.

A spring harrow creates a barrier to moisture evaporation, pulls out cut weeds and plant residues and distributes them evenly over the field surface.

Adjusting the harrow tooth angle:

15° – is the standard setting for most soils and average crop residue levels;

30° – for a high level of crop residues;

50° – on heavy soils with a minimum of crop residues.

A large margin of strength and reliability when working in difficult conditions is provided by pipes made of European steels, from which the central frame and wings are made. Thanks to the lattice design of the frame and its increased rigidity, the cultivator is lightweight, which leads to savings in tractor fuel consumption.

The side sections of the cultivator are able to follow the field topography pretty well relative to the horizon up to ± 7°, providing ideal depth control and soil loosening across the entire working width in fields with difficult terrain.

The checkboard arrangement of tandem wheels on the central frame improves the passage through crop residues without clogging. Two wheels ensure a stable and uniform working depth across the entire working width of the machine and help support the frame.

Thanks to the location of the support wheels on the wings, the cultivator processes the soil at a given depth across the entire working width.

The depth of pre-sowing treatment is adjusted from 2 to 12 cm using a hydraulic system and is additionally mechanically fixed by a set of adjusting stops (clips) made of aluminum alloy located on the central frame. Making it easier to adjust the depth and saving time on setting up the cultivator in the field is done with the help of lanyards (talreeps) located on the support wheels of the wings.

The support wheels are located in the middle of the machine, which makes the Polaris Premium cultivator easy to transport and also makes tight radius turns on headlands easier. The dimensions of the cultivator POLARIS 4 (6;8) (2800 mm in transport position) allow the use of public roads to deliver it to the place of use.

Design of the coupling hitch allows for aggregation with tractors of different manufacturers.

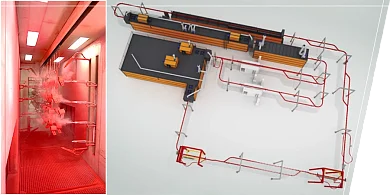

Production line was equipped with a powder coating line -Ideal-line (Denmark). This painting technology makes it possible to produce high-quality paintwork with a guaranteed service life up to 8 years.

Usege of hardware with a strength class, at least 8.8, ensures reliability and durability of exploitation.

* All data and drawings are approximate and non-binding. All rights, to make technical changes to the design reserving to us. Check in more information with the regional manager.