Website loading...

Website loading...

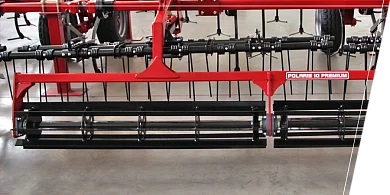

POLARIS PREMIUM is a semi-trailer cultivator designed for resource-saving pre-sowing and steam soil cultivation for cereals, industrial and forage crops, for cutting and combing weeds, as well as for leveling and compaction of the ground surface. Cultivator models are available with working widths from 4 to 12 meters. One of the advantages of this cultivator is its spacious design, which has a high crop residue throughput capacity. The optimum paw spacing promotes intensive mixing and uniform loosening of the soil.

5 rows of paws improve pre-seed preparation, working in fields with a large amount of crop residue.

☑ Effective combination of work units

The checkerboard arrangement of the paws in 5 rows with a paw width of 235 mm allows to work on fields with a lot of crop residues without clogging.

☑ The paws work under the action of vibration

As a result of vibration, the paws thoroughly crush the soil and wear less, thereby reducing operating costs and maintenance frequency.

☑ Robust cultivator design

The frame has a lattice design, it is made of high-strength European steels, it provides the necessary strength and reliability with less weight of the cultivator, resulting in a reduced need for tractor traction force.

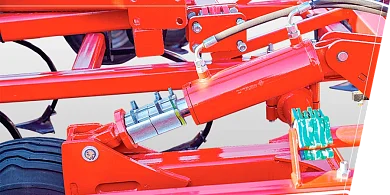

☑ Quick adjustment of working depth

The depth is easily and quickly adjusted by installing clips on the hydraulic cylinder rods of tandem wheels, as well as by adjusting the support wheel lanyards (talreeps) on the cultivator wings.

☑ Effective moisture preserving

Aggressive teeth of a spring harrow comb out cut weeds, destroying capillarity, evenly mix and distribute plant residues on the field, preserving moisture and promoting the most complete and rapid germination of fallen plants.

☑ High-quality soil compaction and leveling

Pressing slatted rollers ensure the crushing of large and small lumps, and also compact the soil in the seed bed area.

The original arrangement of working bodies in 5 rows with a paw width of 235 mm on the cultivator improves pre-sowing soil preparation and allows you to work in fields with a large amount of crop residues without clogging and facilitates the passage of the unit through weeds and crop residues with a height of 150 mm.

The cultivator is equipped with a C-shaped stand 30×30 mm, made of spring steel, with a spiral arm, 235 mm wide, made of steel containing boron, which allows it to easily bypass obstacles hidden in the soil. When the cultivator is operating, the stand creates microvibration, which contributes to the destruction of lumps and layers of soil. Destruction occurs beyond microfractions, which helps restore soil structure.

Compacting rollers with flat strips with a diameter of 320 mm provide crumbling of the soil with a significant predominance of small clods of soil up to 25 mm in size without a compacting effect. Flat blade strips cut through clods and discard soil and crop residues. The vertical force is directed only to the cutting and crushing action. Dropping soil helps mix the soil with crop residues without compaction, which speeds up drying.

Due to the design features of the bearing assembly, the service life of the roller has been increased to 1000 hectares and the time for servicing the unit has been reduced.

Spring-loaded combing harrows allow to pull out cut weeds, crop residues and evenly distribute them over the surface of the field.

Adjustment of the angle of inclination of the harrow tines: 5° - on heavy soils with a minimum of crop residues; 15° is the standard setting for most soils and medium crop residues; 30° - for a high level of crop residues.

Working depth is adjusted using a hydraulic system and additionally mechanically fixed using a set of adjusting stops (clips) made of duralumin alloy and screw pairs located on the support wheels of the wings.

Central frame and fenders are made of pipes with a section of 80x80x6 mm, which provides a large margin of safety and high reliability when working in difficult conditions. At the same time, the use of high-strength European steel pipes allows to reduce the weight of the frame structure while increasing its strength and rigidity, which leads to a decrease in tractor fuel consumption.

Cultivator uses tandem wheels to improve its passability and maintain the depth of soil cultivation.

Cultivator has wings that fold upward using a hydraulic system. The wings of the cultivator make it possible to follow the topography of the field with respect to the horizon up to ±7°. This allows you to maintain a constant cultivation depth in fields with difficult terrain across the entire working width of the machine.

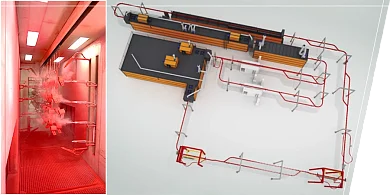

Production line was equipped with a powder coating line -Ideal-line (Denmark). This painting technology makes it possible to produce high-quality paintwork with a guaranteed service life up to 8 years.

Fuel consumption when working with a 180 hp tractor is 7-8 l/ha. Productivity for 1 hour of main time (calculated, at a speed of 12 km/h) - 14.4 ha/h.

* All data and drawings are approximate and non-binding. All rights, to make technical changes to the design reserving to us. Check in more information with the regional manager.