Website loading...

Website loading...

☑ Versatility by changing the angle of attack

The PALLADA design with separate angle of attack adjustment of each disc row from 0° to 30° allows quick and easy adjustment for changes in moisture, crop residue and soil type.

☑ Rigid disc stand

On PALLADA harrows, each disc is mounted on a high-strength firm disc stand, which guarantees uniform soil tillage with minimal ridges in the seeding area.

☑ Individual disc stand

This sturdy disc stand, made of a strong steel wheel with a 7° bend angle, allows working in fields with large amounts of crop residues without clogging.

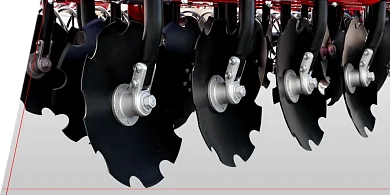

☑ Original disc design

The 9-cutout disc with its unique "lobes" design ensures optimal cutting and mixing of crop residues compared to similar machines.

☑ Disc sharpening angle 20°

The 20° disc sharpening angle ensures reliable deepening and cutting of crop residues as well as uniform wear of the disc over the entire cutting edge while maintaining its sharpening throughout its entire service life.

☑ Mini-till farming technology

The disc harrow is designed for efficient cultivation using Mini-till farming technology and soil preparation for sowing grain, industrial and forage crops.

☑ Trailed disk harrows

The trailed harrows do not require high tractor pulling power, which reduces fuel consumption and the cost of cultivation per 1 ha.

Zone 1 - DISKS:

- destruction of weeds, shredding of crop residues after harvesting crops, loosening of the surface soil layer to pre-sowing condition,

Zone 2 - ROLLERS:

- field leveling and soil compaction with rollers.

The 660 mm diameter discs are designed for greater tillage depth. The disc harrows are equipped with inclined spherical discs with a diameter of 660 mm on individual stands, which increases throughput and cultivation depth and is advantageous with large amounts of crop residues, e.g. after maize harvesting.

Disks are made of European steels with boron content of increased rigidity, which increases their service life up to 100%. The unique method of disk sharpening provides uniform wear of the disk over the entire cutting surface with preservation of its sharpening during the whole service life. To prevent counterfeiting, the manufacturer's branding is placed. Optimum number of notches on the disk for excellent ground crumbling and cutting of post-harvest residues.

The hub with rigid post adapter is a high performance hub designed by for the Pallada and Antares disc harrows.

The design, based on a double row angular contact ball bearing and cassette seal integrated into the housing, gives the product a longer service life than standard hubs;

Lubrication and seals are designed for the life of the bearing.

Design of hub of cutting unit, due to installation of a collar with a cassette seal, increases life of bearing by 60% and reduces time for maintenance by up to 50%.

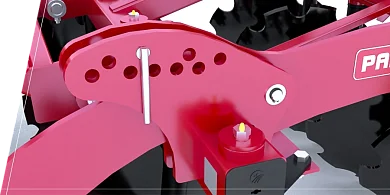

New design for adjusting tillage depth by moving pin between holes. Design made it easier to adjust depth of soil cultivation, while increasing durability of the unit.

The disc harrow design provides independent row adjustment of the disc entry angles from 00 to 300, which allows you to optimize soil cultivation in accordance with different working depths. Thus, this contributes to the improvement of the agrotechnical parameters of soil cultivation, as well as to a decrease in the required tractive effort of the tractor. Bushings are installed on the bar for changing the entry angle of the discs, which makes it easier to adjust the entry angle. A small entry angle provides a shallow surface harrowing, while an increasing of entry angle provides good penetration.

Double-row disc harrows of the PALLADA series are equipped with an incredibly strong frame, which ensures a long-life service, even, in difficult conditions.

Frame was prodused by using high-strength pipes from European steel, which provides reducution of the weight of the frame structure, while increasing its strength and rigidity, as a results, tractors fuel consumption was decreased.

Each harrow disc of the PALLADA is mounted on an individual rack. The absence of a single axis precludes winding of crop residues and clogging of the interdisc space.

Oiler nipples on each hub ensure durability of unit, and oiler nipples at rack attachment essembly, preclude clogging with dust and breakdown of the racks and ensure easy setup of unit.

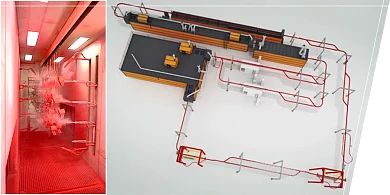

Production line was equipped with a powder coating line -Ideal-line (Denmark). Painting technology makes it possible to produce high-quality paintwork with a guaranteed service life up to 8 years.

The usege of hardware with a strength class, at least 8.8, ensures reliability and durability of exploitation.

| Aggregate type | trailed | |

| Operating width, m | 2.4 | |

| Working speed, km/hr | 12 | |

| Capacity, ha/hour | 2.88 | |

| Tilling depth, mm | 150±30 | |

| Angle of attack of disks, deg. | 0 - 30 | |

| Distance between disk rows, mm | 950 | |

| Diameter of working bodies, mm | 660 | |

| Distance between disk blades, mm | 320 | |

| Transport speed, km/h | 20 | |

| Number of cutting components, pcs. | 14 | |

| Overall dimensions in position, mm | 4 780 х 2 760 х 1 700 | |

| Coupled with tractors with power, more than h.p. | 80 | |

| Weight, kg | 1385 | |

* All data and drawings are approximate and non-binding. All rights, to make technical changes to the design reserving to us. Check in more information with the regional manager.