Website loading...

Website loading...

Equipment Premium includes the BRAVO 400S computer, which belongs to category of accurate equipment with support of Seletron technology - nozzle control of the application of the working fluid and can be used for any treatment in field. It equipped with all necessary electronic control systems, sensors, actuators and other accessories. Versatility of the computer allows it to be used as a navigator and as a computer for complex field spraying control. It can connect to all kinds of accessories in various combinations. Optionally, you can install the BLC boom stabilization system, which makes it possible to automatically adjust the spraying height depending on terrain.

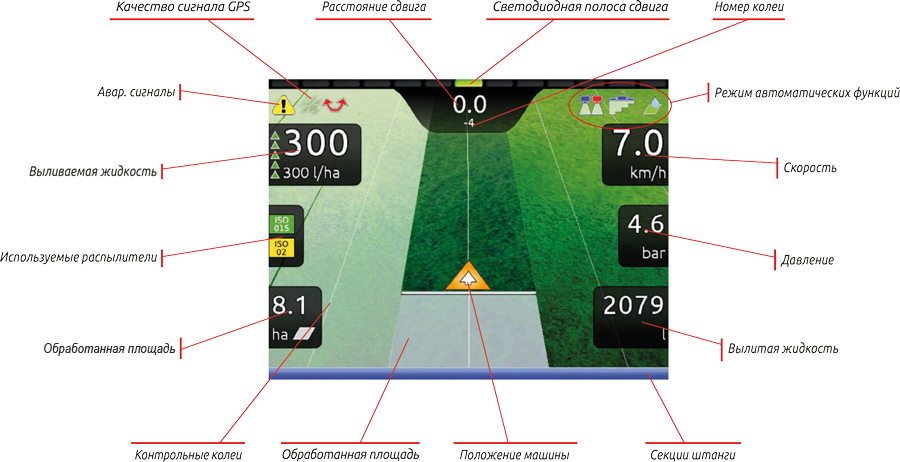

- All graphical and numerical information is presented on one page thanks to the high-resolution 5.7" display.

- Simple intuitive use.

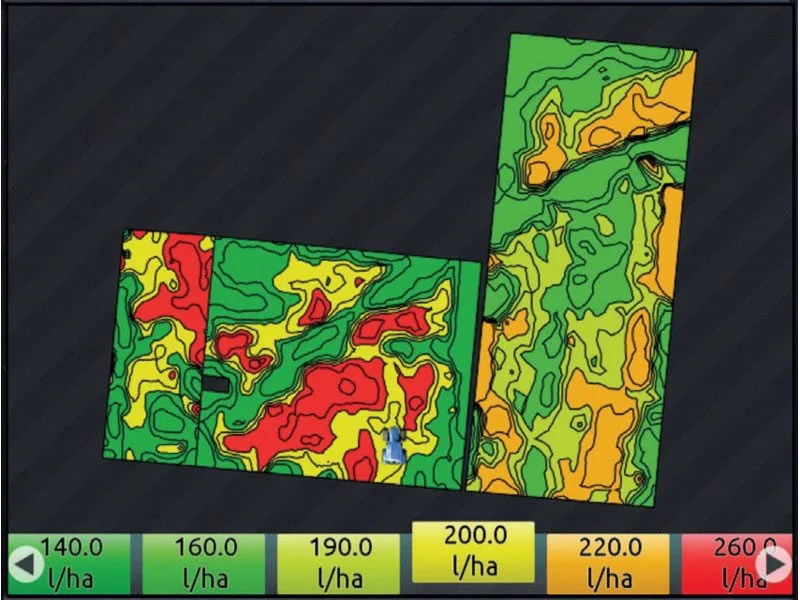

- Application control of fertiling by using instruction cards.

- Ability to control 13 water sections or 104 sprays nozzles (using the Seletron system).

- Connection to full range of GPS and GLONASS receivers Arag. Work in difficult conditions with obstacles (trees, houses, bridges, etc.) with position update 10 times per second (10Hz).

- Ability to manage multiple profiles (user, implement, tractor).

- With the use of the VISIO BLC option - the possibility of automatic stabilization of boom (control of the height and inclination of boom).

- 2 ports for connecting video cameras.

- 2 USB ports and SD card reader.

- Internal memory 2 GB for archiving treatments, maps, tools, tractors, etc.

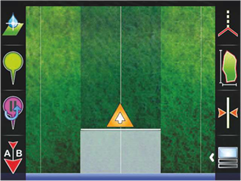

- Works as a navigator if no agricultural equipment is connected.

• All graphical and numerical information is presented on one page.

• Simple and intuitive use.

• Fewer steps to start a new treatment.

• Ability to manage multiple profiles (user, tool, tractor).

• Guided procedure of entry data to facilitate setting of parameters required for processing.

Control of measured application rate function by using cards format Shape.

By marking perimeter, can calculate area and automatically graphically separate inside (green) and outside (brown) portions of field.

Instant access to features -

doesn't cover to view

management-critical information.

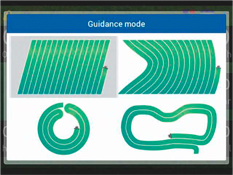

Possible guidance course modes:

by parallel treads,

by curved treads,

by framing and free course.

On complex field view, displays general processing status fields and enlarge specific area.

IBX100 is a multi-platform control unit designed to house software for managing a wide variety of agricultural applications, thus allowing it to be installed on any type of agricultural machinery. A monitor connected to IBX100 receives information directly from unit's software, and is automatically reconfigured for a specific type of operation. Unit can be supplied with A-net or Isobus communication protocol.

SELETRON system allows you to control spraying of each nozzle separately, which is ideal when sprayer is working according to field maps and provides the most accurate spraying of the working fluid. SELETRON system works in conjunction with IBX100 SPRAYER multi-platform control unit.

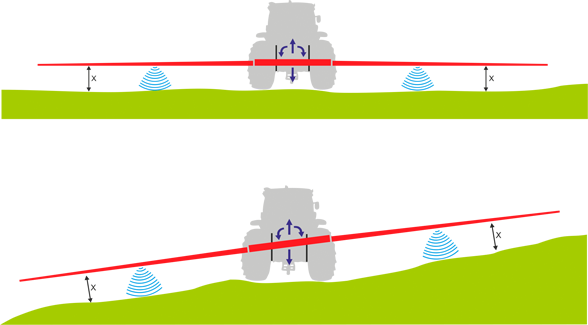

BLC (Boom Leveling Control) kit, which can be installed as an option, maintains same boom distance from uneven ground, providing consistent soil coverage thanks to use of ultrasonic sensors mounted on booms themselves.

- High accuracy and reduced response time.

- Use of standard hydraulic solenoid valves.

- Ability to adapt to existing systems.

AG-Star - for a free signal with an accuracy of 28 cm (in basic equipment Standard, Premium, Premium Plus ); and optional: Smart 6L Double Frequency - for a free signal with an accuracy of 18 cm and a paid signal up to 4 cm.Smart 6L RTK - for a free signal with an accuracy of 18 cm and a paid signal up to 2 cm.

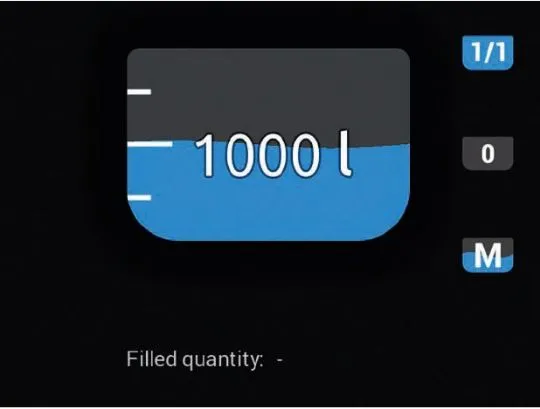

• Indication of actual level of liquid in tank;

• Automatic calibration of level of lquid sensor in tank with ability to export / import tank profile.

• IR lighting for night surveillance

• Bracket with adjustable tilt

• Switch for direct or mirror observation

Technical features

• Color CCD-sensor 1/3 ", 512 x 582 pixels

• Viewing angle 120 °

• Length of connecting cable - 15 meters

• Supply voltage 12 V DC

Driving Assistance System POLARIS ,connected to a Delta 80 / Bravo 400S or Bravo 400SLT, automates the process of driving on both straight and curved routes. During development, special attention was paid to security, using advanced solutions as in hardware and software.

For convenience and acceleration of work, it is possible to connect a multifunctional joystick EXPLORER - new design that allows you to control the main functions of machine (spraying and hydraulic).

| LCD display | Color | |

| Display size | 5,7” / 145 mm | |

| SD card reader | ||

| USB 2.0 data port | ||

| External GPS receiver | ||

| Measurement speed through GPS-receiver | ||

| Connecting video cameras | ||

| Visual navigation | ||

| Connecting to an automatic course guidance system | ||

| Sectional shutdown of spraying | 13 | |

| Spray nozzle shutdown | ||

| Hydraulic control - oil / mix (sections) | 9 | |

| Adjusting the amount of liquid poured out | ||

| Variable rate control using instruction cards | ||

| Automatic section control | By injector (SELETRON system) | |

| Swivel drawbar control | ||

| IBX100 External Electronic Control Unit (ECU) | ||

| Joystick | ||

| Toggle Panels (Water and Oil) | ||

| BLC (Automatic Boom Stabilization System) | Optional | |

* All data and drawings are approximate and non-binding. All rights, to make technical changes to the design reserving to us. Check in more information with the regional manager.