Website loading...

Website loading...

* - In absence of virtual terminal (VT) and task controller unit (Task Controller) on tractor, it is necessary to install DELTA 80 virtual terminal for full control of all spraying functions from the tractor cab.

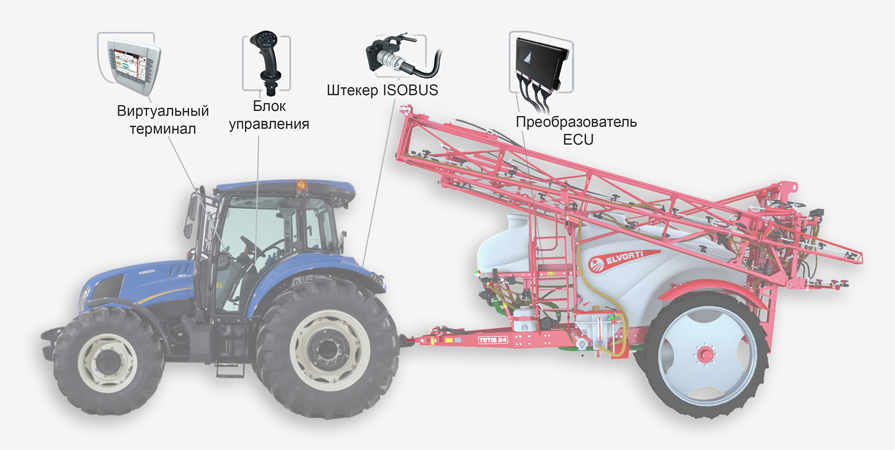

Equipment ISOBUS implies presence of this system on your tractor. ISOBUS (ISO11783) is an international standard with single protocol through which various agricultural implements interact with tractor, regardless of its manufacturer.

This makes it possible, through monitor installed in tractor cab, called Virtual Terminal (VT), to control any agricultural equipment connected to it.

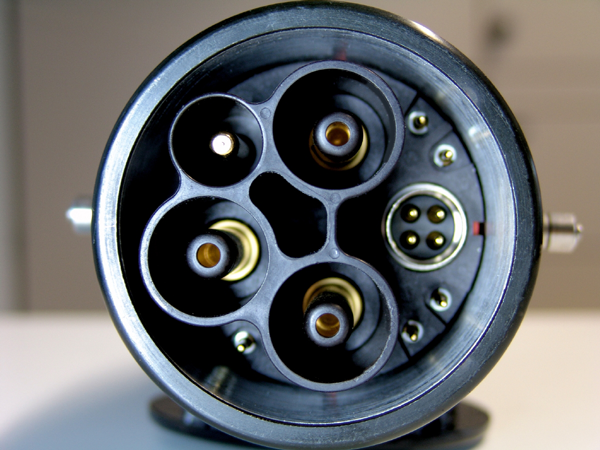

Maximum ease of connection - uses one cable with universal 9-pin ISOBUS plug.

Ease of operation - one monitor is used for any connected farm equipment.

Sprayer must be equipped with an Implement ECU IBX 100 ISOBUS control unit, which not only controls all the sprayer functions, but also controls communication with virtual terminal. In addition, standard provides for possibility of connecting additional control devices (remote controls, joysticks, etc.) to facilitate control of sprayer. These devices are called Auxiliary Input.

Universal 9-pin plug

Main elements of ISOBUS on tractor and sprayer are:

• Virtual Terminal for control from tractor cab,

• Task Controller unit installed in tractor,

• Additional control devices (Auxiliary Input).

The main elements of ISOBUS on a sprayer are:

• Control unit (ECU IBX 100 ISOBUS) between the tractor and the sprayer,

• Universal plug (Isobus plug).

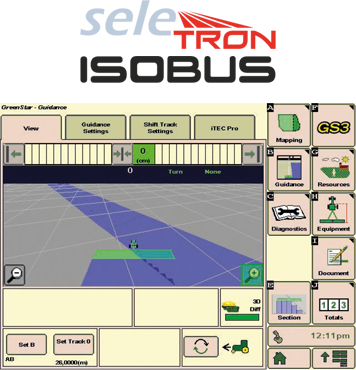

Some of the tested virtual terminals from various manufacturers (John Deere, CNH, Same Deutz Fahr and Fendt),

Sprayer control unit Implement ECU IBX 100 ISOBUS

We offer four options for equipment ISOBUS :

- ISOBUS Seletron - with spray cut-off;

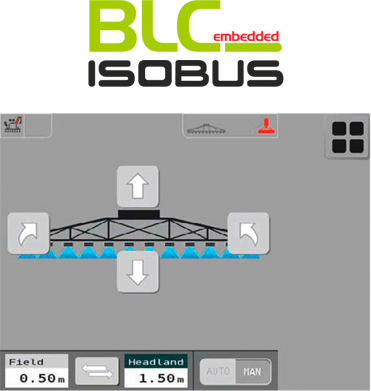

- ISOBUS Seletron + BLC - with spray nozzle shutdown + automatic boom stabilization.

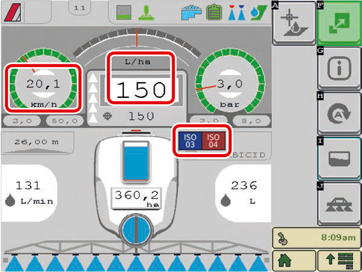

Using virtual terminal, user has access to all advanced functions of the TETIS sprayer at once on one page.

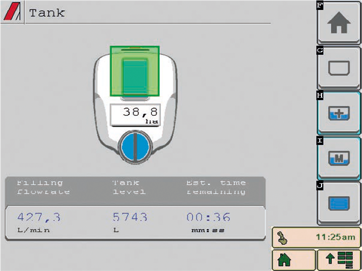

Indication of actual liquid level in tank.

Automatic calibration of level sensor in tank with ability to export / import the tank profile.

Single-nozzle control of SELETRON valves (up to 104) or control of section valves (up to 13). Valves will automatically shut off when trajectories overlap or go out of field. This function is only possible with Task Controller on tractor, otherwise DELTA 80 virtual terminal must be additionally installed.

BLC (Boom Leveling Control) automatic boom leveling function is only available with Task Controller on tractor, and the function can work even without the IBX100 Sprayer ISOBUS control unit. If there is no Task Controller on tractor, then it is necessary to additionally install DELTA 80 virtual terminal and IBX100 Sprayer ISOBUS control unit.

| LCD display | Color | |

| Display size | 8,4” / 213 mm** | |

| Backlit keyboard | ||

| USB 2.0 data port | ||

| WiFi | ||

| Ethernet | ||

| 3G modem | ||

| External GPS receiver | ||

| Measurement speed through GPS-receiver | ||

| Connecting video cameras | ||

| Visual navigation | ||

| Connecting to an automatic course guidance system | ||

| Sectional shutdown of spraying | 13 | |

| Spray nozzle shutdown | ||

| Hydraulic control - oil / mix (sections) | 9 | |

| Adjusting the amount of liquid poured out | ||

| Variable rate control using instruction cards | ||

| Automatic section control | By injector (SELETRON system) | |

| Swivel drawbar control | ||

| IBX100 External Electronic Control Unit (ECU) | ||

| Joystick | ||

| Toggle Panels (Water and Oil) | ||

| BLC (Automatic Boom Stabilization System) | Optional | |

* All data and drawings are approximate and non-binding. All rights, to make technical changes to the design reserving to us. Check in more information with the regional manager.