Website loading...

Website loading...

Seeders mechanical grain ASTRA 6 - designed for row sowing according to the traditional technology of seeds of grain, leguminous and small-seeded crops with simultaneous application of mineral fertilizers and soil compaction in sown rows.

Continuous gear (variator) provides easy and quick adjustment of the seeding rates of seeds and fertilizers, precise and smooth adjustment in a wide range of seeding rates (for grain - from 1.5 to 400 kg / ha, for fertilizers - from 25 to 200 kg / ha ), separate variators for fertilizers and seeds.

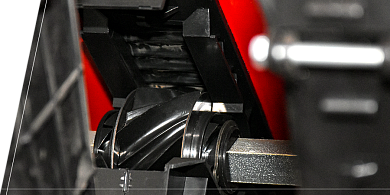

Seeding unit from polymer materials is characterized by maximum accuracy, continuity and smoothness of feeding seeds of various shapes and sizes at a seeding rate from 1.5 to 400 kg / ha. The design of the coil allows for sowing small-seeded crops. to adjust values from 1 to 7, which makes it easier to sow small and large seeds with different rates.

Stainless steel total drive shafts, which increases durability shafts and fertilizer dispensers located on them and eliminates the corrosion of the shafts.

Larger hopper compared to the ASTRA 5.4 seeder. ASTRA 6 has one of the largest bunkers on the market in terms of volume - 1 845 l (grain - 1 245 l, fertilizer - 600 l), which at a wheat seeding rate of 200 kg/ha and a seeding rate of 100 kg/ha of mineral fertilizers allows sowing 6 hectares at one boot.

Visors have been introduced on the rear wall to prevent rain and dew from getting into the area of the fertilizer dispensers, which makes it possible to prevent the hardening of mineral fertilizers directly in the chamber of the fertilizer dispenser.

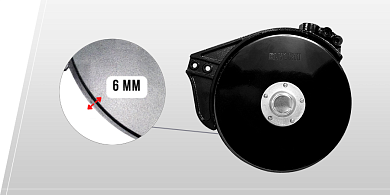

Increased service life of the double-disc opener up to 100%, due to the use of boron-containing steels of increased hardness. The double-disc single-row opener allows sowing in fields with a large amount of crop residues; the uniform design of the coulter-press roller unit allows the coulter to be adjusted to a predetermined depth. ALFA 6 has excellent planting depth control. The result is friendly germination, which contributes to increased yields throughout the field.

Pressure wheels are installed on the ASTRA 4 seeder, which ensures sowing in conditions of different soil moisture. To clean the pressure rollers and ensure a stable sowing depth, scrapers made of wear-resistant DUROSTAT 400 steel are installed, which increases the scraper operation life up to 2000 ha. The finger harrow, as an additional option on the ASTRA 4 seeders, replaces the pressure roller and allows sowing at high soil moisture on different backgrounds.

Electronic control system as standard. ASTRA 6 is equipped with a new version of electronic seed control systems (manufactured by OOO NPF MONADA), which uses new design seed flow control sensors with increased reliability and accuracy in determining the density of the seed flow.

Reinforced transport device with a wheel of increased diameter allows transporting seeders on public roads.

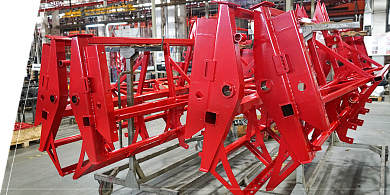

For production of ASTRA 6, high-strength European steels are used, which are 50% higher in terms of rigidity, strength and elasticity of the structure.

Production line was equipped with a powder coating line -Ideal-line (Denmark). Painting technology makes it possible to produce high-quality paintwork with a guaranteed service life up to 8 years.

| Aggregate type | semi-trailed | |

| Operating width, m | 6 | |

| Working speed, km/hr | 9 - 12 | |

| Number of rows, pcs. | 40 | |

| Capacity, ha/hour | 5.4 - 7.2 | |

| Seeding depth of disc openers, mm | 20 - 80 | |

| Opener pressure, kg/sm² | 65 | |

| Seeding rate for grains, kg/ha | 1.5 - 400 | |

| Row spacing, mm | 150 | |

| Seeding rate for fertilizers, kg/ha | 25 - 200 | |

| Box capacity(total) for grains, l (dm³) | 1 245 | |

| Box capacity(total) for fertilizers, l (dm³) | 600 | |

| Overall dimensions for transport, mm | 7 520 х 2 950 х 3 435 | |

| Overall dimensions in position, mm | 4 750 х 6 950 х 1 850 | |

| Coupled with tractors with power, more than h.p. | 90 | |

| Weight, kg | 3 050 | |

* All data and drawings are approximate and non-binding. All rights, to make technical changes to the design reserving to us. Check in more information with the regional manager.