Website loading...

Website loading...

☑ Reinforced frame

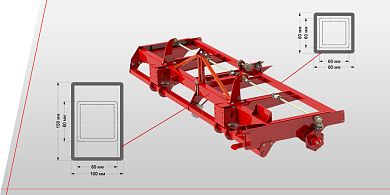

New frame design with larger pipe cross-sections of 100x150 mm and 80x80 mm compared to the previous ASTRA seed drill generation increases reliability and service life. At the same time, it maximises access to the seed drill's working parts for maintenance.

☑ Quick job by the FastTrai transport device

Trailer transport device FastTrai - allows you to transfer the seeder in 2 minutes from the transport position to the working position and vice versa, which saves time and facilitates the work of the machines operator. FastTrai device with a transport width of 2.65 metres for safe travel on public roads.

☑ Up to 20% fuel economy compared to competitors

Drill is made of heavy-duty steel and is ideally suited for use with tractors from 90 hp and saves fuel compared to competitors.

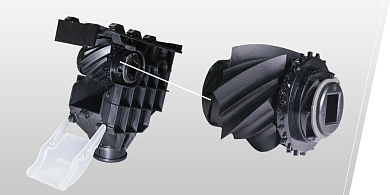

☑ New sowing machine

Made of polymeric materials resistant to aggressive environment and corrosion. It has a double spool: screw spool for sowing cereals and leguminous crops and pin spool for sowing small crops and grass seeds of all shapes and sizes. The sowing spool feeds the seeds smoothly and evenly without traumatising them, which increases the accuracy of seed distribution in the row.

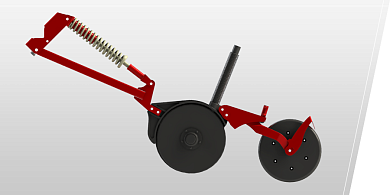

☑ CoultSystem leash system

New design of the CoultSystem drive system with packer roller and improved coulter pressure mechanism up to 75 kg with stiffened spring and hydraulic clamping provides high-quality, uniform sowing according to conventional technology with the possibility of sowing on fields with minimum tillage and small amount of crop residues.

☑ Large hopper – high productivity

Seeder Astra 4 New equipped with a bunker with a large capacity of 1 300 l, which, at a sowing speed of 12 km/h, provides a productivity of 4.7 ha/h.

The new FastTrai trailed and transport device allows you to transfer the seeder in 2 minutes from the transport position to the working position and vice versa, which saves time and makes the work of the operator easier. The basic transport device with wheels of increased diameter and strength provides additional protection against damage to tires by plant stems and other objects on the field surface; with a transport width of 2.95 m, it allows the seeder be moved on public roads.

* The patent for a trailing and transport device issued in accordance with the Law of Ukraine “On the Protection of Rights to Inventions and Utility Models”, registered in the State Register of Utility Models of Ukraine on 08/18/2021.

Sowing machine is equipped with two types of coils:

• screw type for sowing cereals and legumes;

• pin type for sowing small-seeded crops and grass seeds.

Solution ensures a constant and accurate seeding rate from 1.5 to 400 kg/ha and is suitable for seeds of all types, sizes and shapes. Sowing machines are driven by an electric motor and guarantee continuous and uniform sowing, regardless of the speed of the vehicle.

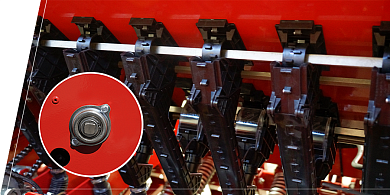

The drive unit shafts of the fertilizer dispensers are made from stainless steel, which increases the durability of the shafts and the fertilizer dispensers, located on them and excludes their corrosion.

Infinitely variable transmission mechanism (variator), which provides easy and quick adjustment of seeds and fertilizers seeding rates ; provides more accurate and smooth adjustment in an increased seeding rate range (from 1.5 to 400 kg / ha) compared to a gearbox.

Electronic control system as a standard. ASTRA NEW is equipped with a new version of electronic seed control systems, which uses a new design seed flow control sensors with increased reliability and accuracy of determining of the seed flows density.

New design of the CoultSystem driving system with a press roller and an improved coulter pressure mechanism of up to 75 kg with a spring of increased rigidity and hydraulic compression allows for uniform deepening of the coulters in the soil, creating a high-quality seed bed for seeds, which is an undoubted competitive advantage of the ASTRA NEW seeder.

Coulters have an adjustable elastic stroke of up to 320 mm, which allows each coulter to individually overcome obstacles and follow the terrain releif.

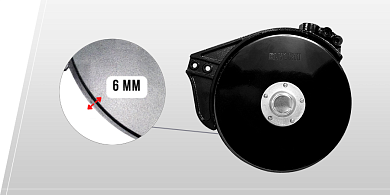

Increased service life of the double-disc opener up to 100%, due to the use of boron-containing, increased hardness steels. The double-disc single-row opener allows sowing at the fields with a large amount of crop residues; the uniformity design of the coulter-press roller unit allows the coulter to be adjusted to a predetermined depth. ASTRA NEW has excellent planting depth control. The result is totally germination, which contributes to increased yields throughout the field.

Optional "narrow" or "wide" press wheels allow sowing in different soil moisture conditions. New reliable depth adjustment system ensures a stable, uniform seed placement depth. DUROSTAT 400 wear-resistant steel wipers are installed to clean the press wheels and ensure a stable seeding depth, which increases the wipers' service life.

Constant hydraulic pressure due to the installed active hydraulic deepening system, which allows you to fix the specified coulter pressure. This function guarantees consistently high quality of seed application into the soil, allows you to maintain the same depth of coulters on uneven surfaces and in the conditions when soil conditions change.

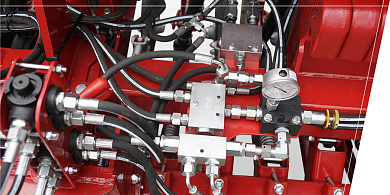

Presence of valves in the hydraulic control system of the seeder allows you to control the operation of the marker with one handle of the hydraulic distributor from the tractor cabin and provides the possibility of combination with tractors that have two pairs of hydraulic outlets

New frame design with increased pipe cross-section of 100×150 mm and 80×80 mm compared to the previous generation of ASTRA NEW seeders, which increases reliability and service life. This also ensures maximum access to the working parts of the seeder for maintenance.

The safety-enhancing steel non-slip footrests are located across the entire width of the drill and provide easy access to the seed hopper for loading.

Hopper is divided into 2 parts for seed 850 litres, for fertiliser 450 litres, it is equipped with technological flaps allowing to combine the 2 parts into one for sowing seeds or fertiliser.

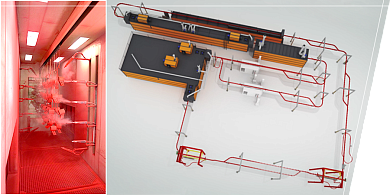

Production line was equipped with a powder coating line -Ideal-line (Denmark). Painting technology makes it possible to produce high-quality paintwork with a guaranteed service life up to 8 years.

| Aggregate type | semi-trailed | |

| Operating width, m | 4 | |

| Working speed, km/hr | 9 - 12 | |

| Number of rows, pcs. | 26 | |

| Capacity, ha/hour | 3.6 - 4.8 | |

| Seeding depth of disc openers, mm | 20 - 80 | |

| Opener pressure, kg/sm² | 75 | |

| Seeding rate for grains, kg/ha | 1.5 - 400 | |

| Row spacing, mm | 150 | |

| Seeding rate for fertilizers, kg/ha | 25 - 200 | |

| Box capacity(total) for grains, l (dm³) | 850 | |

| Box capacity(total) for fertilizers, l (dm³) | 450 | |

| Overall dimensions for transport, mm | 6 400 х 2 700 х 2 800 | |

| Overall dimensions in position, mm | 4 550 х 5 000 х 1 850 | |

| Coupled with tractors with power, more than h.p. | 80 | |

| Weight, kg | 3 000 | |

* All data and drawings are approximate and non-binding. All rights, to make technical changes to the design reserving to us. Check in more information with the regional manager.